- Spare parts

- knives | blades

- shredder cutters | concave cutter

- counter knives | scrapers

- granulator rotor knives | fly knives

- granulator static knives | bed knives

- rotor shear spare parts

- baling press knives

- other blades | pelletising knives

- bolt-on cutting edges

- knife holders | knife pads

- sealing rings | wear rings

- screen baskets

- screen plates

- screen cassettes | screen holders

- screen accessories

- other spares | standard accessories

- electrics | hydraulics | pneumatics

- rotors

- transmission technology

- fastening material

- Manufacturers

- Vecoplan

- Lindner Recyclingtech

- Eldan Recycling

- Andritz Mewa

- Able

- Alpine Hosokawa

- Amni Maschinenbau

- ARP

- Artech

- Austro

- Bano Recycling

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Getecha

- Görgens Mahltechnik

- Gross

- Guidetti

- Haas Recycling

- Hammel Recyclingtechnik

- Herbold Meckesheim

- HSM

- ISVE

- Kueny

- MACPRESSE

- Molinari Recycling

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero

- Rapid Granulator

- Reto Redoma

- Rudnick & Enners

- STF

- Terex

- THM Recycling

- Tria

- Untha

- Vogelsang

- Wagner Shredder

- Wanner

- Weima

- Wipa

- Zato

- Zeno

- Zerma

Condux

Spare parts from CUTMETALL

CUTMETALL supplies precisely fitting spare parts such as rotor knives, stator knives and sieve plates made of high-quality material for Condux machines and systems of various years of construction. You can obtain spare parts and wear parts from us for the following Condux mills, among others:

-

Condux CS 300/600

-

Condux CS 500/1000

-

Condux CS 650/1000

-

Condux CS 650/1200

-

Condux CS 800/1600

-

Condux GS 500/800

» Further information about the manufacturer NETZSCH-Condux (today: NETZSCH Trockenmahltechnik GmbH) can be found below.

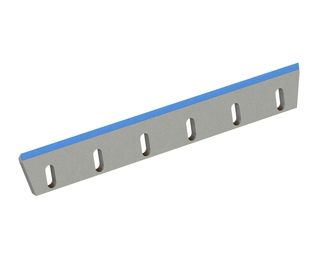

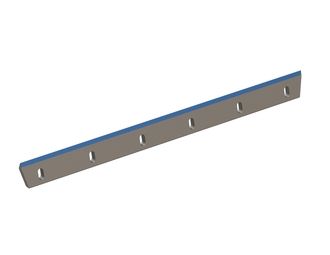

- ROTORMESSER | FLACHMESSER

NETZSCH Trockenmahltechnik GmbH (CONDUX)

Hanau-based NETZSCH Trockenmahltechnik GmbH (formerly NETZSCH-CONDUX Mahltechnik GmbH) is one of the world's leading companies in the recycling industry in the field of dry grinding as well as the processing of dry products. The company is part of the NETZSCH Group's Grinding & Dispersing Business Unit. Long-term experience in mechanical engineering such as granulators, daily contact with customers and consistent development work with more than 100 patents ensure the technical competence and illustrate the quality awareness. Embedded in the NETZSCH Group, the worldwide sales and service network guarantees local customer support for Condux machines.

At the Hanau site, the headquarters of NETZSCH Trockenmahltechnik GmbH, one of the most modern application laboratories in grinding and classifying technology for customer trials is located in addition to the business units administration, development, process engineering, production and sales. This was expanded in 2015 to include a FoodLab for trials under food-compliant conditions.

THE CONDUX PRODUCT RANGE

As a specialist in ultra-fine grinding and classifying, NETZSCH Trockenmahltechnik GmbH offers extensive experience and a diverse range of machines, from laboratory and production machines to complete production lines. Condux is a supplier of a wide range of mills: Fine impact mills, classifier and jet mills as well as fine cutting mills and high-performance fine classifiers. The mills are mainly used in the chemical industry, inorganic materials/minerals, ceramics and in the life science sector for pharmaceutical and food applications. The range of applications for Condux granulators is broad: cellulose, foodstuffs, plastics, plastic fibres, textiles, mineral fibres, wood, paper and other materials are among them.

Thus, the Condux® impact mill is characterised by its conception as a "modular system". The high-speed fine impact mill is suitable for dry fine grinding of a wide variety of products up to a Mohs hardness of 3 - 3.5. In contrast to conventional classifier mills, the grinding disc and the classifier wheel are driven by a common motor. Due to a variety of different size reduction tools, the machine can be universally equipped according to the task and application. Following this concept, NETZSCH refrains from integrating unused features right from the start and only offers what the customer really needs. As a result, Condux achieves a new level of cost-effectiveness. In addition, Netzsch-Condux met a repeatedly expressed customer wish with a narrower gradation of sizes in the smaller range of mills.

With a rotor diameter of 1,000 mm and a working width of 2,400 mm, the company already delivered one of the world's largest granulators in 2008.

Another highlight in the machine portfolio of NETZSCH Trockenmahltechnik GmbH is the pinpoint dry grinding through the use of superheated steam, the jet grinding system s-Jet®. It is the first and only true dry grinding system on the market that achieves grinding finenesses in the submicron or nano range....

Furthermore, the product range from the category of mills by Condux includes various innovative dry mills of the well-known series CGS, ConJet® and CSM, the fine cutting mills of the type SecoMy® as well as fine and ultrafine classifiers of the type series CFS and InlineStar. All these mills, machines and systems from the supplier are available in a wide range of sizes.

DRY GRINDERS

Anyone looking for mills, machines and systems for grinding dry products will find what they are looking for at NETZSCH Trockenmahltechnik GmbH. The spectrum of materials that can be ground with a Condux mill from NETZSCH ranges from A (like activated carbon) to Z (like zinc).

For the grinding of dry products by fine cutting, fine and ultra-fine grinding, the manufacturer has extensive experience and a diverse mill programme for all desired final finenesses. High-performance classifiers for the finest products complete the supplier's programme.

From the individual mill to the complete turnkey grinding system; pressureless or dust explosion-proof systems with a pressure surge resistance of up to 10 bar (g) or also inertisable; material variants in a wide variety of designs including stainless steels with polished surfaces or wear-protected concepts: With its Condux machines, NETZSCH Trockenmahltechnik GmbH offers the right grinding technology in every category!

CUTMETALL products for Condux cutting mills

For your Condux brand shredder, we offer the appropriate spare parts from CUTMETALL, e.g. rotor knives, stator knives and screen plates - precisely fitting wear parts, matched to the respective shredding process.

Do you have questions about our products for your Condux mill?

Your granulator model or the spare part you are looking for is not listed? Would you like to know whether and how the service life and durability of your Condux spare parts can be extended? Please contact us, because not all items are listed online yet. We will be happy to advise you!

Your CUTMETALL Team!

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.