CUTMETALL spare parts for shredders, granulators and other recycling machines

for the manufacturer Hammel

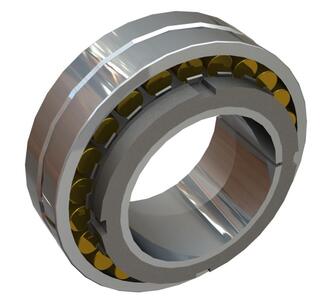

As an operator of a Hammels hammer mill, you will find the right baffle plates, sieve baskets, bearing housings and other spare parts and wearing parts suitable for the Hammel NZ model series, among others, in our spare parts range:

- Hammel NZ 700

- Hammel NZ-S 1000

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.

CUTMETALL - partner, problem solver, and process optimizer for the recycling and shredding industries.

Log in

Did you set the right language?

Then continue to the log-in!

Then continue to the log-in!

*Our offers only apply to commercial customers

Registration

Title