- Spare Parts

- knives | blades

- crown cutters | concave cutters

- counter knives | scraper blades

- granulator rotor knives | fly knives

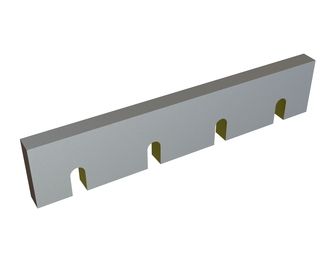

- granulator static knives | bed knives

- rotor shear spare parts

- baling press knives

- other blades | pelletizing knives

- bolt-on cutting edges

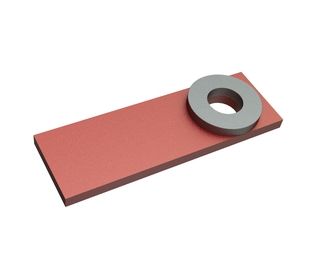

- knife holders | knife pads

- sealing rings | wear rings

- screen baskets

- screen plates

- screen cassettes | screen holders

- screen accessories

- other spare parts | standard accessories

- electrics | hydraulics | pneumatics

- rotors

- transmission technology

- hardware | fastening material

- Manufacturers

- Vecoplan LLC (Retech)

- Lindner Recyclingtech America

- Eldan Recycling

- Andritz Mewa

- Able

- Alpine Hosokawa

- Amni Maschinenbau

- ARP

- Artech

- Austro

- Bano Recycling

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt spare parts

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Görgens Mahltechnik

- Gross

- Guidetti

- Haas

- Hammel Recyclingtechnik

- Herbold Meckesheim USA

- HSM

- ISVE

- Jenz

- Kueny

- MACPRESSE

- Molinari Recycling

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero | Sorema

- Rapid

- Reto Redoma

- Rudnick & Enners

- STF

- THM Recycling

- Tria

- Untha America

- Vogelsang

- Wagner Shredder

- Wanner

- Weima America

- Wipa

- Zeno

- Zato

- Zerma America

Neue Herbold

Spare parts from CUTMETALL

In this section you will find our suitable spare parts and wear parts for various shredders and granulators from Neue Herbold. For example, you can obtain stator knives, rotor knives, clamping bars and screen baskets as well as other spare parts for the following series from Neue Hebold:

-

Neue Herbold HZR single shaft shredder

-

Neue Herbold SM universal cutting mills

-

Neue Herbold SMV granulators

-

Neue Herbold LM granulators

» Further information about the manufacturer Neue Herbold can be found below.

Who is Neue Herbold?

NEUE HERBOLD Maschinen-u. Anlagenbau GmbH, based in Sinsheim-Reihen, Germany, was founded in 1995. The company offers a comprehensive range of machines and plants for shredding and processing all types of plastic waste from production, processing and waste plastic collection, individually tailored to the task in hand. It includes granulators, tube mills, profile mills, shredders, fine grinding plants, washing plants, hot washing plants, dryers, friction washers, intensive washers and separation containers. Connected to this is a special mechanical engineering department that manufactures machines for processing recyclable materials such as computer scrap, insulating materials, aerated concrete blocks and waste wood. This includes hammer mills, guillotine shears, screw crushers and bale breakers.Precise planning oriented towards economic efficiency is followed by production at a high technological level. Constantly accompanied by quality assurance, the result is a product that meets the highest demands on shredding technology.

At the company's location in Sinsheim-Reihen, NEUE HERBOLD employs around 70 people who work in the areas of development, engineering, production, administration and sales. They have a lot of experience and creativity.

The technical sales department serves as the customer's contact and is supported by more than 40 agencies worldwide.

The first step in the recycling process, from large to small and to the finest: pre-shredding, post-shredding, fine grinding

The basis of recycling is the use of single-variety materials. Achieving the desired particle sizes during pre-shredding requires a multi-stage process and different methods of coarse shredding. When waste is turned into recycling material, various shredders, crushers and shears are used in the pre-shredding process. NEUE HERBOLD machines and shredding plants turn residual materials into recyclable materials through proper shredding.Shredders / shredders from NEUE HERBOLD Maschinen- und Anlagenbau GmbH are used in many areas of application. The single and twin shaft shredders / multi-shaft shredders process large materials to be shredded such as bales, compressed bales, plastic drums and IBCs. Typically, single-shaft shredders are used specifically for the pre-shredding of large quantities of large-volume bulky materials, as well as for the pre-shredding of massive lumps and start-up lumps, which are then brought to the desired final sizes in further steps.

Pipe shredders are suitable for the pre-shredding of thick-walled and impact-resistant plastic pipes. Special styrofoam shredders or hammer mills are used for processing styrofoam and insulation materials. The screw crushers effortlessly pre-shred pallets, start-up chunks, large cable drums, insulation boards, aerated concrete and sand-lime bricks as well as other bulky waste and materials.

The shredder also shreds bales, bottles or plastic house waste and prepares them optimally for secondary shredding. In addition, guillotine shears are used to split the material to be shredded, for example fishing ropes, and rubber bales.

NEUE HERBOLD offers solutions and systems, machines and plants for modern and effective plastics recycling.

NEUE HERBOLD single-shaft shredders of the HZR series are equipped with a slow-running rotor shaft. A hydraulically controlled pusher conveys the feed material to the cutting area of the rotor; when the pusher reaches its end position, it automatically returns to its starting position. A powerful drive with attached hydro-clutch ensures a strong pulling force.

NEW HERBOLD shredders of the ZRM series are equipped with slow-running ripping shafts, which are driven electrically or hydraulically. The shredding shafts interlock and thus ensure a rapid shredding process. For an optimal product feed, the shredder can be equipped with a hydraulic pressure ram.

NEW HERBOLD polystyrene shredders are used for shredding EPS and PUR foams. In order to preserve the cell structure of the material to be shredded, unlike granulators for plastic shredding, the shredder does not use a rotor with attached knives - but a knife-less impact cross rotor. The particle size is determined by the variation of the comb spacing as well as by the selected screen perforation.

NEW HERBOLD screw crushers of the SB series are used both as pre-shredding stage for bulky materials such as wooden pallets, cable drums, insulation boards, aerated concrete blocks, sand-lime bricks and for breaking up and dosing bales of compressed waste.

NEW HERBOLD pipe shredder type HZR 1300/x: It is specially designed for the effective pre-shredding of thick-walled, impact-resistant pipes with large diameters (max. 1200 mm) as well as start-up lumps. As a rule, a granulator is installed downstream of the HZR, which reduces the material to a free-flowing grind.

NEW HERBOLD guillotine shears are used for pre-portioning of: multi-filament bales of fibres, bales of tapes, films sticking together, large lumps, rubber bales etc.. They have a torsion-resistant, welded frame construction. The splitting blade, mounted in a solid two-sided support, is moved against a stator by two oversized hydraulic cylinders.

Phase two in the processing of recycled materials: secondary

crushing by means of granulators and hammer mills.

Cutting mills

The various granulators process, among other things, films, long profiles and massive lumps. The material is conveyed via hoppers to the rotor knives rotating on the rotor. In the grinding chamber, stator knives are installed as counter knives. Through the interaction of rotor knives and stator knives, the feed material is crushed until the granulate has reached the desired final size and can fall through the sieve installed in the grinding chamber.

A great advantage of NEUE HERBOLD granulators is the easy access to the grinding chamber: for cleaning as well as for changing material or tools. This reduces downtimes.

NEUE HERBOLD manufactures all machines exclusively from heavy-duty solid steel constructions.

Double bevel cut - Economical and precise

The double diagonal cut ensures a constant cutting gap over the full working width. As a result, the granulators achieve high throughput rates with low noise levels. At the same time, they save energy. In addition, the thermal stress on the material is reduced.

Knife setting gauge

The blade setting gauge supplied with the granulators enables precise presetting of the blades outside the granulators. The customer's employees do not have to laboriously set the exact cutting gap of the knives in the machine, but can do this with the setting gauge under good working conditions outside the machine. This results in improved occupational safety when maintaining the granulators. In addition, the exact fine adjustment of the cutting gap ensures the efficiency and output of the granulators.

Rotor variants

In order to meet the diverse tasks of material requirements in secondary crushing, various rotor designs are used. The different designs enable the processing of soft, hard and impact-resistant plastics.

Tube mills

In tube mills, the mostly thick-walled tubes are fed to the rotor blade with the help of a punch. Load cranes move long and heavy pipes horizontally into the feed trough. Short pipe sections and raw waste from plastics production can be fed in manually. In addition to the "classic" tube mills already described, NEUE HERBOLD also offers the granulators of the LM and SM series tilting hoppers for the size reduction of tubes, with which the tubes are fed and fed to the size reduction unit by means of the gravity principle.

NEW HERBOLD granulators / granulators of the SX series are high-performance granulators. They are equipped with "double bevel cutting geometry". The inclined rotating knives work against likewise inclined stator knives in the mill housing. The rotor and stator knives are adjusted outside the machine in a gauge. The rotor shaft is mounted outside - separate from the grinding chamber.

NEW HERBOLD granulators of the SMV series are universally applicable. This granulator type is tailored to the versatile requirements of a modern recycling plant.

NEW HERBOLD granulators of the SM series are universally applicable. This granulator type is tailored to the versatile requirements of a modern recycling plant.

NEW HERBOLD granulators of the SM series are equipped with "double bevel cutting geometry". The inclined rotating knives work against likewise inclined stator knives in the mill housing. The rotor and stator knives are adjusted outside the machine in a gauge.

The NEW HERBOLD LM cutting mill also has the "double bevel cutting geometry". In the mill housing, the rotor knives and the opposing stator knives are set at an angle to each other. The way this double diagonal cut works ensures a precise cutting gap along the full working width. In addition to lower noise generation, the thermal load on the material fed is reduced. Furthermore, the granulators of the LM series are extremely resilient.

NEW HERBOLD tube and profile mills of the SR and LP series crush long tubes and profiles. The granulators are fed horizontally without pre-cutting and without deflection.

NEW HERBOLD hammer mills of the HM series have a wide range of applications. By equipping the rotor shaft and machine housing with different types of tools, the following applications can be realised, among others: Shredding of wood waste, impact-resistant plastics, electrical scrap and mineral insulation waste.

Mobile shredding and recycling plants

NEUE HERBOLD offers fully mobile plants tailored to the respective process objective (shredding, washing, screening, separating and drying), including mobile shredding and recycling plants.

The necessary individual components are connected to each other; the size and design of the plant is determined in such a way that mobility - including placing the plant in a container or on a truck - is possible without restriction.

Available rotor variants for our granulators

Since not every rotor is optimally suited for every task, NEUE HERBOLD offers variants. In this way, the customer's ideas can be optimally met.

Fine grinding

In addition to pre- and post-shredding, fine grinding is used to obtain the desired granulates. For this purpose NEW HERBOLD fine mills of the ZM series are used. The specially designed impact disc mills enable the fine grinding or pulverisation of medium-hard, brittle to impact-resistant plastics (e.g. PE, PVC, PC).

For optimum fine grinding of the material to be ground, the particle size of the material to be processed should not exceed 6 to 8 mm. Starting materials can be, among other things, ground material from shredded window profile waste or pipe waste. The ground material is preferably fed to the dosing device from a silo via a discharge aid, the storage container. Full or empty detectors in the hopper automatically control the feed. The ground material is fed to the NEUE HERBOLD impact disc mill via a load-dependent controllable dosing device.

The ground material to be pulverised is fed into the high-performance fine shredders in granular form. The powder is then pneumatically discharged. The plastic powder can now be classified by downstream screening. Inductive metal separators are installed upstream of the grinding process to separate metallic or magnetic foreign bodies. For the removal of aluminium and other non-magnetic foreign bodies, classifier systems are offered.

The centrifugal forces in the centrifugal ring accelerate the granulate and drive it through the grinding discs. The NEUE HERBOLD fine mills and impact disc mills operate without sieving. The oversize determined during sieving is returned to the impact disc mill for further grinding until the desired final particle size is achieved. The NEW HERBOLD impact disc mills are easily accessible and maintenance-friendly. As an option, they have a temperature control system which can reduce the temperatures during comminution with the help of water mist. The supplied moisture escapes via the exhaust air.

The advantages of the NEUE HERBOLD mills are above all the high efficiency due to the high throughput rate as well as the low thermal load on the material to be ground and the long service life of the tools. Another advantage is the quick and easy change and readjustment of the tools.

Suitable noise protection cabins are part of the offer and project planning.

NEW HERBOLD granulators are certified according to CE safety standards.

NEUE HERBOLD fine grinding mills / impact disc mills of the ZM series are specially designed for the fine grinding (pulverisation) of medium-hard, brittle to impact-resistant plastics. The feed material to be pulverised is in granular form. Depending on the size, the granulate to be pulverised may have a maximum grain size of 6-8mm. Depending on the task, the downstream connection of a screening machine with the return of the oversize material can be easily integrated.

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.