- Spare Parts

- knives | blades

- crown cutters | concave cutters

- counter knives | scraper blades

- granulator rotor knives | fly knives

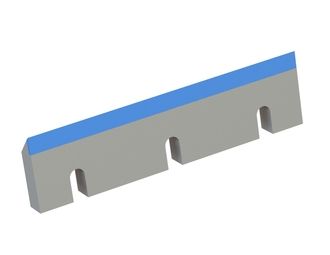

- granulator static knives | bed knives

- rotor shear spare parts

- baling press knives

- other blades | pelletizing knives

- bolt-on cutting edges

- knife holders | knife pads

- sealing rings | wear rings

- screen baskets

- screen plates

- screen cassettes | screen holders

- screen accessories

- other spare parts | standard accessories

- electrics | hydraulics | pneumatics

- rotors

- transmission technology

- hardware | fastening material

- Manufacturers

- Vecoplan LLC (Retech)

- Lindner Recyclingtech America

- Eldan Recycling

- Andritz Mewa

- Able

- Alpine Hosokawa

- Amni Maschinenbau

- ARP

- Artech

- Austro

- Bano Recycling

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt spare parts

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Görgens Mahltechnik

- Gross

- Guidetti

- Haas

- Hammel Recyclingtechnik

- Herbold Meckesheim USA

- HSM

- ISVE

- Jenz

- Kueny

- MACPRESSE

- Molinari Recycling

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero | Sorema

- Rapid

- Reto Redoma

- Rudnick & Enners

- STF

- THM Recycling

- Tria

- Untha America

- Vogelsang

- Wagner Shredder

- Wanner

- Weima America

- Wipa

- Zeno

- Zato

- Zerma America

Alpine Hosokawa

Spare parts from CUTMETALL

For your shredding plant of the brand Hosokawa Alpine our assortment contains a large number of suitable CUTMETALL spare parts such as rotor knives, stator knives, screens and other spare parts and wearing parts suitable for, among others, the following model series of Hosokawa Alpine:

-

Alpine Rotoplex Ro granulator

-

Alpine Dura Line DL shredder

-

Alpine Compact-Line CL granulator

-

Alpine Ultraplex UPZ Fine Impact Mill

» More information about the manufacturer Hosokawa Alpine in the following.

Who is Hosokawa Micron Ltd?

Hosokawa Micron Limited, Runcorn, Rivington Road, Whitehouse Industrial Estate United Kingdom, was formed in 1989 by the amalgamation of Alpine Process Technology and Hosokawa Mikropul and joined by LE Stott to become a specialist in the development, manufacture and installation of machines, systems and equipment for powder processing, particle processing, agglomeration, hygienic filling and weighing, containment and nanotechnologies. Not only granulators and shredders, but multi-tasking fruit and vegetable disintegrators or flexible compact isolators for precision manufacturing, for example. Milling, classifying, compacting and enclosing are typical jobs performed by the company's highly specialised products.

Hosokawa Micron Limited is a member of the Hosokawa Micron Group founded in Osaka in 1916. Today, Hosokawa Micron it is a world leader in providing process solutions in the fields of powder and particle processing technology and blown film technology. Hosokawa Micron Group maintains laboratories and other facilities for research, engineering, manufacturing and service throughout Asia/Oceania, the Americas and Europe. All companies of the Hosokawa Group benefit from adoption of the Hosokawa Gen4 digital technology platform.

From the UK base in Runcorn, Cheshire the Hosokawa Micron Limited provides a full testing, design, installation and commissioning service to a wide range of industries in UK, Eire and overseas. Hosokawa Micron Ltd is the worldwide agent for Hosokawa Micron Milling and Hosokawa Containment.

The engineering skills and latest production technologies of Hosokawa ensure that the high level of performance of the machines, application of our extensive processing know-how and partnership approach to development of new technologies and processing solutions are in demand by small and large, blue chip companies alike.

Hosokawa Micron Ltd is proud to offer customers a single source supply for integrated processing systems and component machinery to meet individual requirements and seek to set new standards in powder processing technologies that exceed expectations and deliver significant competitor advantage. The philosophy of Hosokawa is not just to offer a standard machine but to work alongside the customers and their engineering teams to provide value added in-house solutions to processing problems.

Example applications for Alpine shredders:

Advantages of an Alpine granulator or shredder

- Energy efficiency: Many of the granulators and shredders feature low energy consumption. This reduces operating costs.

- Convenient handling: The machines are usually easily accessible. This facilitates cleaning and maintenance.

- No pre-sorting necessary: With the Polyplex PPC shredder-cutting mill, customers can feed different plastic waste at the same time. This saves them time and effort in advance!

- For films and fibres: The Dura-Line DL shredder is particularly suitable for fibrous material. Its cutting system prevents them from wrapping around the shaft.

- Special fineness: With the AFS fine cutting mill, customers achieve grinding finenesses of a few hundred µm up to 2 mm.

- The classic: The solid cutting mill Rotoplex RO is a real all-rounder, especially when high cutting forces are required and high throughput rates are to be achieved.

1. FILM RECYCLING

All machines in a Hosokawa Alpine film recycling plant are precisely optimised ans matched to the respective requirements in terms of film, throughput, feed, transport routes, etc., both in terms of design and customer-specific layout. In addition to the optimal matching of the components, a very stable design and control of the individual components is an essential part of the reliable overall solution.

THE RIGHT MACHINES FOR PRODUCTION

The ROTOPLEX RO granulator

The concept as well as the heavy-duty machine design allow the use for any material that can be cut; especially when high cutting forces are required and high throughputs have to be handled. The classics in the ALPINE granulator range with continuously refined technology. Sizes from 15 - 500 kW.

Areas of application- Plastic waste of all types and shapes, especially films, chunks, profiled material, chips, etc.

- Natural and synthetic rubber, vulcanised rubber

- Cable waste: Copper cable, aluminium cable, lead cable, electronic scrap, etc.

- Cuttable materials: fibres, glass fibre waste, leather, paper

- Universally applicable for all cuttable materials such as plastics, films, fibres, rubber, leather, etc.

Plastic waste of all types and shapes, especially films, chunks, profiled material, chips, etc.

- Natural and synthetic rubber, vulcanised rubber

- Cable waste: Copper cable, aluminium cable, lead cable, electronic scrap, etc.

- Cuttable materials: fibres, glass fibre waste, leather, paper

- Universally applicable for all cuttable materials such as plastics, films, fibres, rubber, leather, etc.

2. CABLE RECYCLING

The products used for granulation in cable recycling impress with their proven, extremely stable design. Durable machine materials such as nodular graphite cast iron can be combined with wear protection specially adapted to the processing of old cables. A modular system of pre-shredding, disintegration, entanglement and dry-mechanical separation ensures reliable processing of different feed sizes and compositions as well as an unrivalled recovery rate.

THE RIGHT MACHINES FOR PRODUCTION

The ROTOPLEX RO granulator (see above, jump link)

The ULTRAPLEX UPZ fine impact mill

The Ultraplex UPZ Fine Impact Mill is a versatile but simple to operate size reduction system with exchangeable grinding elements.In short, the Alpine Ultraplex UPZ Fine Impact Mill can be tailored to match the individual requirements of every customer. The versatility of different available milling elements fulfils a wide variety of demands on the end-product, for example:

- High fineness with sharp top cut

- Products that are low in fines with good flow properties

- Production of powders with a high bulk density

- Production of powders with a high mass fraction within a defined particle size range

This impact mill’s versatility comes from the easily interchangeable milling elements, making the machine adaptable to suit a wide variety of feed materials.

Ultraplex UPZ Mills can be equipped as pin mills without a sieve, with one rotating pin disc and one stationary one. They can also be equipped as a beater mill with a beater disc, swing, or plate beater unit, for operation with grinding tracks or sieves. The overall result is a host of practice-oriented and perfectly coordinated equipment combinations.

The UPZ impact mill is used in many branches of industry (particularly chemicals, food, animal feed, and pharmaceuticals) for a wide variety of applications. Its versatility can be summarized as follows:

- Beater disc, pin discs, swing beaters and plate beaters, sieves and grinding tracks

- End-product fineness in the range of ultra-fine 50 µm to approx. 5 mm, depending on the grinding equipment installed

- Generously dimensioned mill door for easy cleaning and exchange of grinding elements

Specifications

- Cast housing with standard discharge available up to machine size 1000 UPZ

- Welded housing with either standard or tangential discharge in mild steel or stainless steel (e.g. 1.4541, 1.4571, 1.4404) for all machine sizes

- Explosion-pressure-shock-proof design for a maximum explosion overpressure of 10 bar (g) with type test as defined in the ATEX Directive 94/9/EC

- Application-specific pharma designs, i.e. polished, monobloc, SIP/CIP, isolator integration

- Connection flange order-specific

- Bearing unit protected against dust by rinsing air (automatic air intake or forced rinsing)

- Bearing unit with special sealing rings, gas-tight design also possible

- Bearing unit permanently lubricated or designed for relubrication

- Safety interlock

- Optional wear-protection elements

- Grinding track ejector optional

3. RECYCLING OF EXTRUSION PARTS

Hosokawa Alpine systems are reliable and also convince economically with clever solutions like special-purpose machineries. The classic solution is the combination of a granulator of the type Rotoplex or Compact-Line with a downstream dedusting step. A new solution sets new standards in terms of easy cleaning, low space requirements and uncomplicated material feeding. It is a new type of shredder-cutting mill that combines the self-dosing properties of a shredder with the product finenesses of a cutting mill. It is possible to process feed material lengths of up to 6 m or start-up lumps of up to more than 100 kg without any problems. The machine concept offers easy access to the grinding chamber, which enables quick and thorough cleaning.THE RIGHT MACHINES FOR PRODUCTION

The Rotoplex Ro granulator (see above, jump link)The Compact-Line CL cutting mill (see above, jump link)

The AFS fine cutting mill

Grinding takes place in stages via a tapered grinding gap from the inside to the outside. Depending on the task, the tooth geometry of the one-piece grinding discs is determined in order to achieve optimum results while minimising maintenance and wear.Areas of application

Alpine fine cutting mills of the AFS type are used for the fine grinding of soft to medium-hard plastics in the fineness range from a few hundred µm up to 2 mm. It does not matter whether the material is fresh or ground from granulators. The end product obtained is characterised by a smooth cubic shape with very good flow properties and thus optimal further processability.4. RECYCLING PLASTIC MOULDED PARTS

Even difficult products (high volume, high weight, bulky shape) can be recycled with the right equipment. The solution lies in combining the right components for the task at hand with detailed solutions tailored to market requirements.THE RIGHT MACHINES FOR PRODUCTION

The Rotoplex Ro granulator (see above, jump link)

The Compact-Line CL granulator (see above, jump link)

The AFS fine cutting mill (see above, jump link)

PREBREAKER

The degree of size reduction attained is dependent upon the physical properties and nature of the process feed material. Hooked, hard faced hammers rotate between fixed, hard faced anvils to provide cutting and shearing of materials ranging from soft and friable through to tough and resilient while conveying product to the discharge. Low rotational speed and high torque enables tough materials to be reduced in size with minimum wear.Hosokawa Micron Prebreakers are size reduction units designed for light to heavy duty requirements.

- Robust construction, low maintenance

- Ability to withstand shock loads

- Available to 150kW power for the most demanding applications

- Optimum hammer/anvil orientation

- Particle size controlled by orifice plate

Hosokawa Micron Prebreakers are available in a range of chemical and hygienic designs.

Typical Applications of Prebreaker:

- Chemicals

- Food

- Petfoods/Animal by-products

- Pharmaceuticals

- Rubber and plastic

- Pulp and paper

RUBBER CHOPPER

For size reduction of bales of natural and synthetic rubbers to facilitate blending with other ingredients or dissolving.- Low maintenance

- Minimised noise, minimal wear

- Low temperature rise

- Energy efficiency

- Controlled end particle size

The Hosokawa Micron Rubber Chopper’s extra heavy-duty design can shred bales of rubber and plastic in seconds at a maximum torque of 3Kw/rpm. The machine operates at low speeds (top 40 rpm) and generates enormous torque. A bale is dropped into the hopper inlet, the sharp edges of rotating hammers bite into the bale and shear it into chunks against the anvils. As the chunks are pushed through the barrel they are repeatedly chopped into smaller pieces until they pass through the orifice plate. Cut-off knives shear the product as it exits the plate governing the final size of the material being extruded.

Typical Applications of Rubber Chopper

- Butadienes

- High Impact Polymers

- Isoprenes

- Nitriles

- Styrene Butadiene

- Butyrates

- Natural Rubbers

- Butyls

- Reclaim

Optional: Rubber Chopper Bale Ram Feeder

Designed for the positive and automated feeding of problematic grades of synthetic rubber. Providing Chopper performance increase, higher machine utilisation, no operator intervention.- Heavy duty manufacture

- Oversize pneumatic cylinder operation for maximum bale transit

- Low maintenance

- No requirement for chopper unit main drive motor upgrade or machine speed increase

- Standard fit to 15 inch Chopper unit without modification

- ATEX certified design available for European installations

The DURA-LINE DL shredder

Dura-Line shredders are characterised by a heavy, torsion-free stand construction, solid material cutter shafts and special perforated screens for exact determination of the ground material. The control system allows variable settings to be programmed and recipes to be stored for different materials. Even the most difficult material is ground reliably and trouble-free. The cutting system prevents films or fibres from wrapping around the shaft.The CONTRAPLEX CW II wide-chamber pin mill

Alpine Contraplex Pin Mills typically deliver high grinding fineness in the range 10 – 500µm, especially with brittle and crystalline materials.The following industry areas are relevant for Contraplex mills:

- Minerals powders: calcium carbonate, fillers, calcium hydroxide. Coating of fillers with stearic acid, silane, etc.

- Pharmaceutical: vitamins, pharmaceutical auxiliaries

- Food: fatty proteins, spices (nutmeg, cloves, pepper, etc). Disintegration of powders for protein shifting, corn starch, lactose, cacao, fish meal

- Chemicals: fine grinding of plastics (e.g. TPU, PA), pesticides, hydrotalcite, pigments (e.g. ultramarine), carboxymethylcellulose (CMC)

- Recycling: fine grinding of rubber

The Contraplex CW wide-chamber housing prevents coating formation, build up and thus blockages in the machine and is especially suited for moist, oily, fatty or hygroscopic products.

With the Contraplex pin mill, both pin discs are driven and rotate in opposite directions, making high relative speeds possible. Their robust drive delivers energy efficient operation.

Contraplex Pin Mills, C & CW Specifications

- Welded housing with either standard or tangential discharge

- Mild steel or stainless steel (e.g. 1.4541, 1.4571, 1.4404) for all machine sizes.

- Pin discs and pins made of special steel

- Cast housing with standard discharge available for machine sizes 250 to 630

- Bearing unit protected against dust by air rinsing (automatic air intake or forced rinsing)

- Bearing unit permanently lubricated or designed for re-lubrication

- Safety interlock

Options:

- Pharma design

- Explosion-pressure-shock-proof design for a maximum explosion overpressure of 10 bar (g) with type test as defined in the ATEX Directive 94/9/EC

- Wear-proof pins

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.