- Spare Parts

- knives | blades

- crown cutters | concave cutters

- counter knives | scraper blades

- granulator rotor knives | fly knives

- granulator static knives | bed knives

- rotor shear spare parts

- baling press knives

- other blades | pelletizing knives

- bolt-on cutting edges

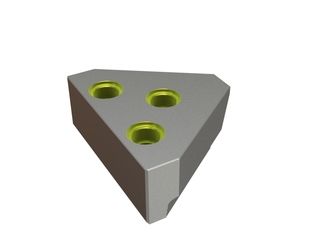

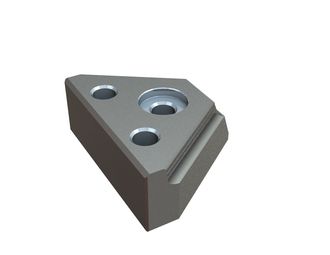

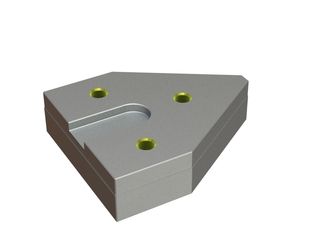

- knife holders | knife pads

- sealing rings | wear rings

- screen baskets

- screen plates

- screen cassettes | screen holders

- screen accessories

- other spare parts | standard accessories

- electrics | hydraulics | pneumatics

- rotors

- transmission technology

- hardware | fastening material

- Manufacturers

- Vecoplan LLC (Retech)

- Lindner Recyclingtech America

- Eldan Recycling

- Andritz Mewa

- Able

- Alpine Hosokawa

- Amni Maschinenbau

- ARP

- Artech

- Austro

- Bano Recycling

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt spare parts

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Görgens Mahltechnik

- Gross

- Guidetti

- Haas

- Hammel Recyclingtechnik

- Herbold Meckesheim USA

- HSM

- ISVE

- Jenz

- Kueny

- MACPRESSE

- Molinari Recycling

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero | Sorema

- Rapid

- Reto Redoma

- Rudnick & Enners

- STF

- THM Recycling

- Tria

- Untha America

- Vogelsang

- Wagner Shredder

- Wanner

- Weima America

- Wipa

- Zeno

- Zato

- Zerma America

Molinari Recycling

Spare parts by CUTMETALL

For your Molinari shredder, our range includes a large number of suitable CUTMETALL spare parts such as knives, bed knives, concave knives, wear plates and other spare parts and wear parts suitable for, among others, the following Molinari machines:

-

Molinari TPM 2500

» Further information on the manufacturer Molinari below.

Who is MOLINARI?

Molinari, based in Lenna (Bergamo), Italy, is an international industrial company that designs and manufactures machines for shredding all types of waste.

Molinari machines are characterised by reliability, robustness and low environmental impact. They also have an innovative design.

Molinari is part of the Meccanica Gervasoni group of companies.

THE MACHINES

The TPm seriesThe single-shaft primary shredder of the TPm series is the perfect machine for the shredding sector: thanks to the trapezoidal blades and the reduced speed, it allows excellent performances in the categories of energy consumption, production and maintenance.

The structure of the machine is made of very thick electro-welded plates that ensure robustness and reliability over a long period of use. Shredding is carried out by the cutting action of the rotating blades on fixed counter-blades mounted on an adjustable crosspiece. A pusher guarantees the shredding of even bulky objects.

The motorisation varies according to the requirements of the material to be treated. The hydraulic motor with corresponding control unit is matched to a planetary reduction gear. A shielding grid is located under the rotor.

Unlike the shredders already on the market, this machine makes it possible to obtain a ground product with a very homogeneous and defined size based on the size of the holes in the grid. The side of the square holes can vary from 40 to 400 mm. Hourly production increases as the size of the hole increases. The management PLC allows the customer to change some operating parameters independently or follow preset processing cycles.

The TP Series

The TP Series model is the perfect machine for shredding scrap tyres and producing alternative fuels. The machine can shred car and truck tyres up to 120 cm in diameter as well as some types of industrial and agricultural tyres.

The outstanding feature of this shredder is its low speed. It consists of two independent rotors with opposite rotation. The cut is made by the action of the rotating blades on the fixed blades installed on a crossbar between the two rotors. The rotating blades and the fixed blades are interchangeable.

The distance between them is also adjustable to always achieve a clean cut. The machine can be equipped with a screening grid to obtain a product with defined dimensions suitable for use as substitute fuel.

The hTP series

For material types such as unsorted municipal waste, the h series shredder complements the TP series. The fixed blades are welded to a movable central crosspiece and are made of wear-resistant material.

The central crosspiece is designed to absorb shocks and, in the case of material that cannot be shredded, to lower so that it comes out easily. The crosspiece is moved by its own hydraulic unit.

The MT series

The Molinari single-shaft shredder is an innovative machine in the field of shredding technology: it offers higher productivity compared to traditional post-shredders with a pusher, with the same output, or allows a reduction in energy consumption of up to 30% for the same production.

Unlike other machines on the market, the Molinari single-shaft shredder does not require a pusher to push the material against the rotor: Thanks to its special, patented design with hollow rotor and offset knives, it is able to grip the material without the help of other devices. And it has the great advantage of working continuously and with constant energy absorption.

The rotor speed is adjustable from 100 to 300 rpm to fully exploit the production characteristics in terms of quality and quantity.

The toothed rollers installed above the crushing chamber have the function of breaking up any voluminous agglomerates and ensuring correct feeding of the grinding chamber, because they are directly controlled by the rotor's energy absorption.

It is equipped with safety joints that protect the rotor in case of non-conforming material: The grid is mechanically released, releasing the material contained in the grinding chamber.

The screen is located on the rotor and covers 50 per cent of its surface. It is manufactured according to customer specifications. The MT3000 model is the ideal machine for the production of alternative fuels because it guarantees the size and homogeneity of the treated material.

Helyos

Helyos is the perfect machine for iron-free granules and alternative fuel.

It is a granulator with a vertical axis and opposite cutting planes. This special technology makes it possible to easily separate the iron contained in used tyres.

The operating principle in the field of ELT processing is unique and enables the rubber to be expelled quickly from the grinding chamber. This prevents overheating and immediately separates the rubber from the steel wire, which can then be easily removed with the help of a magnetic separator.

Helyos makes it possible to adjust the size of the rubber granulate output according to the customer's market requirements.

The ability to adjust the rotors can produce a 40 x 40 mm chip suitable for use as an alternative fuel, or a 15 mm granule more suitable for rubber recovery as a secondary raw material. In both cases, the steel freed from the rubber can be recycled economically.

The MP series

The Molinari mill is highly appreciated on the market for its robustness, ease of maintenance and excellent performance in grinding rubber chips.

The entire series of machines for recycling ELT provides for water cooling of the fixed blades, the bearing supports and the rear conveyor.

The patented rotor with staggered blades allows excellent performance in terms of productivity and energy consumption. Due to the Molinari offset blade rotor, it is the only machine that can reduce energy costs.

The system for lowering the grid holder by means of a hydraulic cylinder allows quick and safe control of the grinding chamber....

It is possible to work with sieves whose holes have a diameter of 3, 4, 5 mm or more.

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.