- Spare Parts

- knives | blades

- crown cutters | concave cutters

- counter knives | scraper blades

- granulator rotor knives | fly knives

- granulator static knives | bed knives

- rotor shear spare parts

- baling press knives

- other blades | pelletizing knives

- bolt-on cutting edges

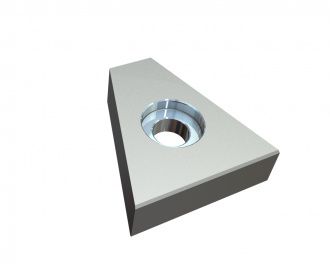

- knife holders | knife pads

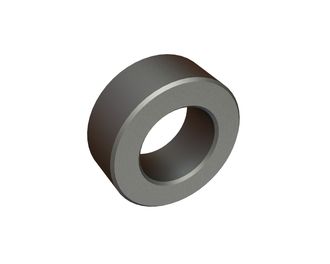

- sealing rings | wear rings

- screen baskets

- screen plates

- screen cassettes | screen holders

- screen accessories

- other spare parts | standard accessories

- electrics | hydraulics | pneumatics

- rotors

- transmission technology

- hardware | fastening material

- Manufacturers

- Vecoplan LLC (Retech)

- Lindner Recyclingtech America

- Eldan Recycling

- Andritz Mewa

- Able

- Alpine Hosokawa

- Amni Maschinenbau

- ARP

- Artech

- Austro

- Bano Recycling

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt spare parts

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Görgens Mahltechnik

- Gross

- Guidetti

- Haas

- Hammel Recyclingtechnik

- Herbold Meckesheim USA

- HSM

- ISVE

- Jenz

- Kueny

- MACPRESSE

- Molinari Recycling

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero | Sorema

- Rapid

- Reto Redoma

- Rudnick & Enners

- STF

- THM Recycling

- Tria

- Untha America

- Vogelsang

- Wagner Shredder

- Wanner

- Weima America

- Wipa

- Zeno

- Zato

- Zerma America

Doppstadt spare parts

Spare parts from CUTMETALL

CUTMETALL supplies precisely fitting spare parts for Doppstadt duplex shredders, such as knives, counter-knives, knife holders and sieve plates made of high-quality material.

» Further information about the manufacturer Doppstadt can be found below.

Who is Doppstadt

Doppstadt Beteiligungs GmbH, based in Velbert, Germany, is a modern company with tradition. Founded in 1965 by Werner Doppstadt as an agricultural company, the group of companies is now a leading, recognised partner in environmental technology worldwide. The group includes Doppstadt Calbe GmbH, Doppstadt Umwelttechnik GmbH and Doppstadt Systemtechnik GmbH.

The experts in these companies plan, realise and manufacture plants and shredding technology for mobile and stationary use. For customers in more than 40 countries Doppstadt products make an important contribution to the protection of the environment and the conservation of resources.

Doppstadt machines are used in the following fields of application:

Waste wood processing Construction waste Biogut Landfill Mining Refuse derived Fuel Processing Commercial waste Composting Compost sives overflowWASTE WOOD PROCESSING

Waste wood is a valuable resource whose processing is becoming increasingly important. Doppstadt advises, plans and constructs high-performance complete solutions, both mobile-modular and stationary, which fit exactly to the requirements on site and can be integrated into existing components - including convincing services for a future-proof, successful operation.

Examples for waste wood:

- Bulky waste wood from separate collection

- Industrial waste wood

- Waste from wood processing such as furniture industry, flooring/panel production

- wooden packaging such as pallets, boxes, cable drums

- Construction and demolition wood such as solid wood, chipboard, shuttering wood

- Doors, windows, structural timber, railway sleepers

- Depending on the quality level, waste wood is used either energetically (combustion in biomass power plants) or materially (wood-based materials industry).

Machines

Mobile shredding, grinding, separation, screening

Slow-speed shredder models of the METHOR and INVENTHOR lines

High-speed shredder models of Grinder Line AK

Mobile pre-shredding and fine shredding

is possible with models of the DZ line

Trommel screen: models of lines 518, and SM

Star screen: models of the SELECTOR and DST lines

Spiral shaft separation: models of the SELECTOR and SWS lines

Stationary shredding, grinding, separation, screening

Slow speed shredder models of the lines CERON and DW

Models of Grinder Line AK

Trommel screen: models of the SM and SST lines

Spiral shaft separation: SPLITTER line models

CONSTRUCTION WASTE

Whether new construction, demolition or renovation: building rubble and mixed building waste is produced during every construction project. Rising landfill costs, higher demands on landfillability and an ever increasing demand for secondary raw materials of good quality: these factors call for innovative solutions for the recovery and production of valuable partial fractions from building rubble and mixed construction waste. However, mixed construction waste cannot simply be completely landfilled due to its organic components. Pure thermal disposal, on the other hand, is too expensive or technically not feasible. Therefore, it must first be separated according to density so that inert material can be deposited and the remaining materials can be thermally or even materially recycled. Doppstadt offers different separation processes which - combined to an individual complete solution - effectively select and separate in:- Alternative fuels

- Plastics and wood for energy recovery

- Stones and metals

Machines

Mobile screening and separating

Trommel screen: models of lines 518, and SM

Star screen: models of the SELECTOR and DST lines

Spiral shaft separation: models of the SELECTOR and SWS lines

Wind shifting: the AIRFLEX 1500 model

Sink-float separation: the HDS-L model

Stationary screening and separating

Trommel screen: models of lines SM and SST

Spiral shaft separation: SPLITTER line models

Wind shifting: Models of the WS line

Sink-float separation: models of the HDS line

BIO-WASTE

Bio-waste is separately collected. This can be separated into solid and liquid phase with the Doppstadt screw press, just like canteen kitchen waste, leftovers and overlaid, packaged food. Biowaste, such as kitchen waste, is produced during the processing of organic material:

- Liquid phase as biogas substrate for wet fermenters

- Solid phase for energetic use

- Liquid phase as agricultural fertiliser

Stationary solid-liquid separation

Screw press: the DSP 205

Stationary mixing/homogenisation

Mixer: the DM 215E

Mobile composting

Compost spreaders: models of the DU line

Mobile separation

Spiral shaft separation: models of the SELECTOR and SWS lines

Trommel screen: models of lines 518 and SM

Stationary separation

Spiral shaft separation: SPLITTER line models

Trommel screen: models of the SM and SST lines

LANDFILL MINING

The issue of landfill reclamation is becoming increasingly relevant - whether it is to create new building land in conurbations, to remediate soil and groundwater or to recover residual materials for material and energy recovery. Landfill site decommissioning is usually carried out to provide future landfill space and to recover secondary raw materials such as the metals Fe and NE.Alternative fuels

secondary raw materials (ferrous and non-ferrous metals)

Machines

Mobile screening and separating

Star screen: models of the SELECTOR and DST lines

Spiral shaft separation: models of the SELECTOR and SWS lines

Wind shifting: the AIRFLEX 1500 model

Stationary screening and separating

Spiral shaft separation: SPLITTER line models

Wind shifting: Models of the WS line

Mixing/homogenisation: the mixer DM

REFUSE DERIVED FUEL PROCESSING

The greatest challenge in the production of substitute fuels (RDF) lies in the inhomogeneity of the waste streams to be treated. The materials that are processed with Doppstadt plants mainly comprise

- bulky waste, residual waste from industry and commerce

- Commercial waste similar to household waste, production-specific commercial waste, construction site waste, sorting residues etc.

Machines

Mobile pre- and secondary shredding, separation and wind shifting

Shredders (low-speed) : models of the METHOR and INVENTHOR lines

Trommel screen: models of lines 518 and SM

Star screen: models of the SELECTOR and DST lines

Wind shifting: the AirFlex 1500 model

Shredders: Models of the AK line

Stationary pre- and secondary shredding, separation and wind shifting

Shredders (low-speed) : models of the CERON and DW lines

Trommel screen: models of lines SM and SST

Wind shifting: WS line models

Shredders: AK, KIMO and CURO line models

COMMERCIAL WASTE

The requirements and legal regulations (e.g. Commercial Waste Ordinance) for handling commercial waste are constantly increasing - high-quality materials are to be recovered, processed and recycled to a greater extent. The aim is to recover secondary raw materials, cleanly separate fractions or generate high-quality substitute fuels. Doppstadt offers all necessary individual components - whether as a mobile modular or stationary complete solution or as a supplement to existing machines in order to meet the specified sorting and recycling quotas. Thus the following fractions can be generated:Wood A1 or A2 / A3

Fe Metals

Foils / paper-board and cardboard

Alternative fuels

Fine Minerals

Machines

Mobile pre- and secondary shredding, separation and wind shifting

Shredders (low-speed) : models of the METHOR and INVENTHOR lines

Trommel screen: models of lines 518 and SM

Star screen: models of the SELECTOR and DST lines

Spiral shaft separation: models of the SELECTOR and SWS lines

Wind shifting: the AirFlex 1500 model

Stationary pre- and secondary shredding, separation and wind shifting

Shredders (low-speed) : models of the CERON and DW lines

Trommel screen: models of the SM and SST lines

Spiral shaft separation: SPLITTER line models

Wind shifting: Models of the WS line

COMPOSTING

The composting of biogenic waste such as green waste or organic waste produces high-quality soil conditioners and homogeneous fuels that can be used for thermal recycling. New legal requirements regarding the quality of the products produced are constantly creating new challenges here. Composting distinguishes two cycles: green waste composting and biowaste composting. In green waste composting, the material is first shredded, then the shredded material is placed in heaps and finally screened. Screening not only serves the purpose of particle size fractionation, but also has the important function of removing non-biological impurities. Through various separations, plastic and synthetic materials are separated just as effectively as iron parts and stones. At the end of the process, a high-quality, natural humus fertilizer is produced.Machines

Mobile: fine shredding, composting, screening and separation

Shredders (high-speed): Models of the AK line

Compost spreaders: models of the DU line

Trommel screen: models of lines 518, and SM

Wind shifting: the AIRFLEX 1500 model

Sink float separation: the HDS-L model

Stationary: fine shredding, composting, screening and separation

Shredder: Models of the AK line

Trommel screen: models of the SM and SST lines

Wind shifting: Models of the WS line

Sink float separation: models of the HDS line

COMPOST SIEVE OVERFLOW

Without treatment, compost sieve overflow must be disposed of expensively by thermal means. Careful separation and treatment of the screen overflow can reduce costs and produce several useful fractions. Doppstadt's machines offer the right technology for each individual process step, reliably sifting, separating and cleaning - whether as a customised complete plant or as a useful addition to existing components.Mobile separation and wind shifting

Spiral shaft separation: models of the SELECTOR and SWS lines

Wind shifting: the AirFlex 1500 model

Sink flaot separation: the HDS-L model

Stationary separation and wind shifting

Spiral shaft separation: SPLITTER line models

Wind shifting: Models of the WS line

Sink float separation: model of the HDS line

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.