- Spare Parts

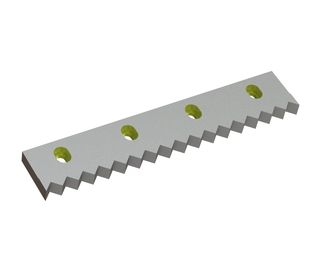

- knives | blades

- crown cutters | concave cutters

- counter knives | scraper blades

- granulator rotor knives | fly knives

- granulator static knives | bed knives

- rotor shear spare parts

- baling press knives

- other blades | pelletizing knives

- bolt-on cutting edges

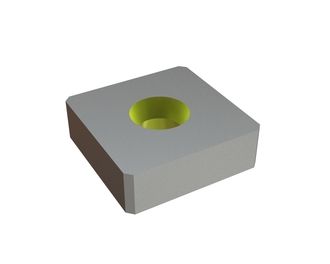

- knife holders | knife pads

- sealing rings | wear rings

- screen baskets

- screen plates

- screen cassettes | screen holders

- screen accessories

- other spare parts | standard accessories

- electrics | hydraulics | pneumatics

- rotors

- transmission technology

- hardware | fastening material

- Manufacturers

- Vecoplan LLC (Retech)

- Lindner Recyclingtech America

- Eldan Recycling

- Andritz Mewa

- Able

- Alpine Hosokawa

- Amni Maschinenbau

- ARP

- Artech

- Austro

- Bano Recycling

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt spare parts

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Görgens Mahltechnik

- Gross

- Guidetti

- Haas

- Hammel Recyclingtechnik

- Herbold Meckesheim USA

- HSM

- ISVE

- Jenz

- Kueny

- MACPRESSE

- Molinari Recycling

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero | Sorema

- Rapid

- Reto Redoma

- Rudnick & Enners

- STF

- THM Recycling

- Tria

- Untha America

- Vogelsang

- Wagner Shredder

- Wanner

- Weima America

- Wipa

- Zeno

- Zato

- Zerma America

ARP

Spare parts from CUTMETALL

As an operator of an ARP plant, you can obtain from us the appropriate spare parts for your shredder, such as rotor shears for the following ARP models:

-

ARP EZ 100

-

ARP CS 5000

» More information about the manufacturer ARP is available below.

Who is ARP GmbH & Co.KG

Wolfgang and Klaus Riegert founded the company in 1984 in the Black Forest, more precisely in Alpirsbach-Peterzell, Baden Württemberg. There they started with the production of supplier parts for the regional industry.Since then ARP has not been operating regionally for a long time. Today the family business operates a worldwide sales network for recycling and processing plants. Service and sales partners operate in 21 countries in Europe, Asia and North and South America and ensure that ARP plants, components and products are available around the globe.

ARP offers plants for the following industries: Metals, food, tyres, oil filters, hazardous waste.

Example applications:

- metal recycling » More.

- hazardous waste » More.

- oil filter preparation » More.

- tyre recycling » More.

- food » More.

- organic waste » More.

- yoghurt cup recycling » More.

Recycling Systems: Standard Machines

Thanks to the ARP modular system, special accessories and equipment, the company can supply the optimum shredding machine for almost any application. Experts advise customers in detail about the wide range of technical possibilities and work out individual plant solutions for them. This also includes an objective profitability analysis.1. Metal recycling

ARP is an expert for integrated, fully automated system solutions and an experienced partner in metal recycling. The company takes care of the professional recycling and processing of chips, punching waste and sprues. Special attention is paid to the recovery of recyclable materials, energy saving and increasing efficiency in the manufacturing industry.

2. Hazardous waste

Special waste requires special treatment. It is shredded in several stages, centrifuged and then sorted into fractions and sorted into different containers.

3. Oil filter reconditioning

The complete oil filters are crushed in several stages. The oil-containing material is then fed into a centrifuge for oil separation. The dry material is then separated into the metal and paper fractions and sorted into different containers.

4. Tyres

ARP offers mobile and stationary systems for the disposal of used tyres. They separate rubber and metal components. They then shred the rubber to a defined grain size in several aisles during an automated process using appropriate conveying equipment.

5. Food

What to do with rejects? A conveyor belt feeds them to a roller system for emptying. The contents and packaging are then separated exactly and the plastic thus obtained is crushed, cleaned and dried.

6. Recycling of organic waste from household waste for biogas plants

The plant is filled directly by truck with organic waste. The plant shreds it in several stages, reliably sorts out metallic components and stores the usable components for further processing in the biogas plant.

7. Yoghurt cup recycling

Rejects (filled, sealed yoghurt cups) are transported via a conveyor belt to a roller system for emptying. There, yoghurt and packaging are carefully separated. The separated plastic is crushed, cleaned and dried.Special solution

Sensitive and hazardous hazardous waste is subject to strict requirements for waste management. We take care of special solutions so that you can concentrate on your core business

ARP systems

Single shaft shredder

The material is shredded between the cutting blade and the cutting bar. The use of a sieve guarantees an even size of the granulate as well as a transportable, pumpable and absorbent quality.

Two-shaft shredder

The material is shredded between the cutting knives in both longitudinal and transverse directions. The use of a sieve or retention and stripping systems guarantees an even size of the granulate. It achieves a transportable, pumpable and absorbent quality.

Shredders

For special requirements, ARP offers ready-made shredding solutions from its standard range. On request, the company will modify them according to the customer's specifications.

Chip pumping stations

For pumping technology, ARP offers individually optimised pumping stations for chip and grinding technology designed for the respective task.

Vacuum components

With above-ground chip disposal using vacuum suction technology, dry or low-drip, pre-crushed chips are transported via a vacuum pipe system and fed to a central processing unit. The ARP programme includes

- Vacuum suction locks and slide valves

- Separator

- Filter separator

- Liquid separator

Centrifuges

ARP centrifuges are suitable for separating chips and cooling lubricants. The centrifuged and thus dried chips achieve a significantly higher market value when sold to the waste management companies. In addition, the cooling lubricant can be reused on the production machines.

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.