- Spare Parts

- knives | blades

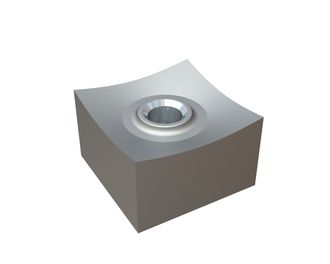

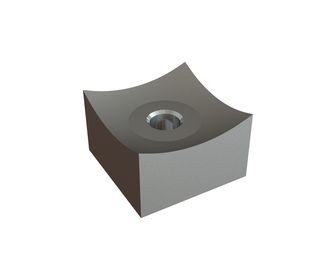

- crown cutters | concave cutters

- counter knives | scraper blades

- granulator rotor knives | fly knives

- granulator static knives | bed knives

- rotor shear spare parts

- baling press knives

- other blades | pelletizing knives

- bolt-on cutting edges

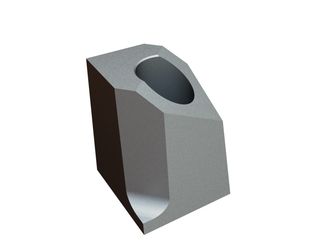

- knife holders | knife pads

- sealing rings | wear rings

- screen baskets

- screen plates

- screen cassettes | screen holders

- screen accessories

- other spare parts | standard accessories

- electrics | hydraulics | pneumatics

- rotors

- transmission technology

- hardware | fastening material

- Manufacturers

- Vecoplan LLC (Retech)

- Lindner Recyclingtech America

- Eldan Recycling

- Andritz Mewa

- Able

- Alpine Hosokawa

- Amni Maschinenbau

- ARP

- Artech

- Austro

- Bano Recycling

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt spare parts

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Görgens Mahltechnik

- Gross

- Guidetti

- Haas

- Hammel Recyclingtechnik

- Herbold Meckesheim USA

- HSM

- ISVE

- Jenz

- Kueny

- MACPRESSE

- Molinari Recycling

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero | Sorema

- Rapid

- Reto Redoma

- Rudnick & Enners

- STF

- THM Recycling

- Tria

- Untha America

- Vogelsang

- Wagner Shredder

- Wanner

- Weima America

- Wipa

- Zeno

- Zato

- Zerma America

ISVE

Spare parts from CUTMETALL

Our range of spare parts for your ISVE Recycling shredder includes rotor blades, counter blades, cutting crowns and other spare parts and wearing parts suitable for the ISVE MR model series (ISVE MR 40-100, ISVE MR 40-120), among others.

» Further information about the manufacturer ISVE in the following.

Who is ISVE

Since 1997 ISVE has implemented the development of its own Recycling division, which offers a complete range of systems for grinding and reusing industrial waste.ISVE grinders are appreciated in various sectors for their high robustness and reliability. They offer the possibility of grinding any wood essence, even with the presence of polluting materials, such as nails, plastic, cardboard, etc.

For all these systems, maintenance is minimal.

In addition, all ISVE machines can be joined together with loading belts, deferrization and aspiration systems to constitute real transformation lines.

For ISVE any industrial waste recycling need is an opportunity to measure its own technical capacity, and since 1977 it has made available the widest range of shredders, grinders and granulators on the market.

For each specific demand from the client, ISVE comes with its own technical staff and special carpentry unit: plans and executes custom-made hoppers, planned bases and solutions to make your production and recycling line machines operative.

ISVE is reliable due to its own post-sale service with spare parts computerized management, with detailed computation available to the client 24 hours a day and a workshop dedicated to assistance and repair.

Single-shaft shredders “MR” series

Pusher-drawer single shaft grinders.Machines studied for the grinding of other materials and high cutting endurance, such as plastic blocks and plates, different types of wood, paper, extruded polymer tubes, etc. A hydraulic drawer is pushing the material against the rotating tools holder which performs the pre-rupture and the grinding. In case of overloading, the rotor and the drawer automatically reverse the movement to release the material and avoid structural overloads. In the end the product is screened by a perforated grate to determine the final size of the ground material.

Single-shaft shredders

Model MR 17-40

The MR 17-40 single-shaft equipped shredder is particularly suitable to shred small wastes with high resistance. A hydraulic control unit allows driving the pusher drawer. Thus, the product to be grinded is pushed towards a tools-holder rotor causing its crushing. Thanks to a screen it is possible to select the final dimension of the shredder material.

Model MS 22-60

The MS 22-60 single-shaft equipped shredder is particularly suitable to shred high-consisting wastes. A hydraulic control unit allows driving the pusher drawer. Thus, the product to be grinded is pushed towards a tools-holder rotor causing its crushing. Thanks to a screen it is possible to select the final dimension of the shredder material.

Model MR 40-80

The M 40-80 single-shaft equipped shredder is particularly suitable to shred high quantities of industrial wastes. The heavy structure makes the machine suitable to realize an heavy use. A hydraulic control unit allows driving the pusher drawer. Thus, the product to be grinded is pushed towards a tools-holder rotor causing its crushing. Thanks to a screen it is possible to select the final dimension of the shredder material.

Model MR 40-100

The MR 40-100 singe-shaft equipped shredder is particularly suitable to shred high quantities of industrial wastes. The heavy structure makes the machine suitable to realize an heavy use.

Model MR 40-120

The MR 40-120 singe-shaft equipped shredder is particularly suitable to shred high quantities of industrial wastes. The heavy structure makes the machine suitable to realize an heavy use.

Model MR 40-140

The MR 40-140 singe-shaft equipped shredder is particularly suitable to shred high quantities of industrial wastes. The heavy structure makes the machine suitable to realize an heavy use. A hydraulic control unit allows driving the pusher drawer. Thus, the product to be grinded is pushed towards a tools-holder rotor causing its crushing. Thanks to a screen it is possible to select the final dimension of the shredder material.

Model MR 48-200

The MR 48-200 single-shaft grinder is suitable for processing large quantities of industrial waste. The heavy structure makes the machine suitable for heavy duty. The pusher drawer is operated via a hydraulic power unit. The product to be ground is thus pushed towards a tool-holder rotor which causes it to be crushed. Thanks to a grid, the final dimensions of the ground can be selected.

Double-shafts shredder

Heavy 2- shafts shredders with loading hoppers, equipped with high quality cutters with low rotation speed for a lower energy consumption and noise reduction. Grinding group designed for a maximum productivity and operation, with anti-wear enhanced thickness steel tools. If subject to excessive loading, the machine automatically performs a temporary inversion of the blades movement to avoid overloading. Electronically controlled by PLC. A wide range of accessories for loading and unloading operations.The machine is composed by a two-shafts shredder with rotary blades and specer combs. Once the material is into the hopper and the machine is ON, the shredder catches the material and begins to cut it grossly. Thanks to the high cutting torque and the different conformation of the cutters group it’s possible to shred pieces made of different materials. The process is automatically regulated by a PLC that can be programmed through the display placed on the electric board.

B-70/80S

Multipurpose machine suitable for shredding an enormous number of waste materials- even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood, rags, plastic blocs leather, small tyres, paper, cardboard, packaging, polyethylene banding, plastic film, etc.

B-70/100S

Multipurpose machine suitable for shredding an enormous number of waste materials- even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood, rags, plastic blocs leather, small tyres, paper, cardboard, packaging, polyethylene banding, plastic film, etc.

B-70/120S

Multipurpose machine suitable for shredding an enormous number of waste materials- even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood, rags, plastic blocs leather, small tyres, paper, cardboard, packaging, polyethylene banding, plastic film, etc.

Isve 4-shafts shredders for bulky waste.

Fit for small and medium enterprises allow to reduce the production waste volume for reusing or disposal, with minimum power consumption, little noise and high reliability. Equipped with control PLC to settle their operation, they come with interchanging screen to determine the final size of the ground material. They can operate with plastic materials, cardboard, wood, packaging, residual skin and leather, barks, cans, bundles and others. Maintenance can be made directly by the user with specific keys and technical book. Traditional “Tritotutto” 4-shafts industrial shredders represent the vintage I.S.V.E. shredding line on the market for over 10 years. Industrial shredders are machines able to shred all types of waste, whether urban or industrial such as plastic materials, paper, cardboard, wood, packaging, shells, fruit stones, leather and hide waste, bark, cans, tyres, copper items.40-80S

Medium sized multipurpose machine suitable for shredding an enormous number of waste materials- even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood, rags, plastic, leather, tyres, paper, cardboard, packaging, polyethylene banding, plastic film, PET bottles, milk bottles, different types of containers, upholstery, bumpers, small trunks, tarpaulin, etc.

60-80S

Medium sized multipurpose machine suitable for shredding an enormous number of waste materials- even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood even large sized, rags, plastic, leather, small tyres paper, cardboard, packaging, polyethylene banding, plastic film, PET bottles, milk bottles, different types of containers, paper documents, upholstery, bumpers, small trunks, tarpaulin, etc.

80-80S

Medium sized multipurpose machine suitable for shredding an enormous number of waste materials- even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood even large sized, pallets, rags, plastic, leather, tyres paper, cardboard, packaging, polyethylene banding, plastic film, PET bottles, milk bottles, different types of containers, paper documents, plastic scraps, upholstery, bumpers, small trunks, tarpaulin, etc.

80-80SA

Medium sized multipurpose machine suitable for shredding an enormous number of waste materials- even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood even large sized, pallets, rags, plastic, leather, tyres paper, cardboard, packaging, polyethylene banding, plastic film, PET bottles, milk bottles, different types of containers, paper documents, plastic scraps, upholstery, bumpers, small trunks, tarpaulin, etc.

80-90S

Medium sized multipurpose machine suitable for shredding an enormous number of waste materials- even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood even large sized, pallets, rags, plastic, leather, tyres, paper, cardboard, packaging, polyethylene banding, plastic film, PET bottles, milk bottles, different types of containers, paper documents, plastic scraps, upholstery, bumpers, small trunks, tarpaulin, etc.

100-90S

Very versatile “medium-heavy” shredder, suitable for shredding numerous waste materials, even bulky ones. It can be inserted in line for continuous operation. Recommended for shredding even large pieces of wood, pallets, rags, plastic, leather, tyres, paper, cardboard, packaging, polyethylene tapes, plastic films, PET bottles, metal sheet containers, various containers, upholstery, faesite, bumpers, trunks, waxed tarpaulins, paper documentation, plastic scraps, extrusion start and end sprues, etc.

120-90S

Very versatile “medium-heavy” shredder, suitable for shredding numerous waste materials, even bulky ones. It can be inserted in line for continuous operation. Recommended for shredding even large pieces of wood, pallets, rags, plastic, leather, tyres, paper, cardboard, packaging, polyethylene tapes, plastic films, PET bottles, metal sheet containers, various containers, upholstery, faesite, bumpers, trunks, waxed tarpaulins, paper documentation, plastic scraps, extrusion start and end sprues, etc.

80-100S

Medium sized multipurpose machine suitable for shredding an enormous number of waste materials – even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood, even large sized, pallets, rags, plastic, leather, tyres, paper, cardboard, packaging, polyethylene banding, plastic film, PET bottles, milk bottles, different types of containers, paper documents, plastic scraps, upholstery, bumpers, small trunks, tarpaulin, etc.

100-100S

Medium sized multipurpose machine suitable for shredding an enormous number of waste materials – even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood even large sized, pallets, rags, plastic, leather, tyres, paper, cardboard, packaging, polyethylene banding, plastic film, PET bottles, milk bottles, different types of containers, paper documents, plastic scraps, upholstery, bumpers, small trunks, tarpaulin, etc.

120-100S

Medium sized multipurpose machine suitable for shredding an enormous number of waste materials – even very large. It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood even large sized, pallets, rags, plastic, leather, tyres, paper, cardboard, packaging, polyethylene banding, plastic film, PET bottles, milk bottles, different types of containers, paper documents, plastic scraps, upholstery, bumpers, small trunks, tarpaulin, etc.

120-130S

Heavy machine for hard works. Thanks to the the great power of cut, this machine is suitable to be used as single pre-crusher for voluminous materials or as secondary shredder to control the size by using an evacuating screen. Recommended for shredding track and car bumpers, polypropylene tanks, bulky scraps, tyres, leather, rags, metal cans, hospital and ship scraps, etc.

Combined shredder and granulator: ISVE COMBI

Machines for the reemployment of production waste which combine a 4-shafts shredder and a granulator to get directly pieces of 4-10 mm. Grinding of large materials and remarkable cutting endurance with convenient investment and operation costs. Handled materials: kegs, cans, plastic bowls, car shockproof devices, tanks, rubber, paper, cardboard, polyethylene tapes, PET bottles. A control PLC provides the operation of the device, by keeping constantly in contact the shredder and the granulator. Sequential power on and power off system to facilitate the cleaning between changes of material. The Combi series can be equipped with loading tapes, metal detector, ground material dust exhaust systems and big-bag packing.Combined shredders Combi: Model 40/80S – GR 500

The unit is made up of a model 40/80S shredder group working in line with a GR 500 granulator.

Combined shredders Combi: Model 60/80S – GR 500

The unit is made up of a model 60/80S shredder group working in line with a GR 500 granulator.

Combined shredders Combi: Model 80/80S – GR 700

The unit is made up of a model 80/80S shredder group working in line with a GR 700 granulator.

Blade granulators GR series

Plated granulators to refine non-ferrous materials: plastic, cardboard, wood, confidential paper documents, etc. For a good price/performance ratio, these mills are used for the grinding and refining of thick materials requiring an enhanced cutting. All the models are equipped with a rotating and fixed blades wearing offsetting, a double wheel and programming for water cooling. They can be additionally equipped with a full rotor or with a continuous blade open rotor. Interchangeable hoppers, loading conveyor belts, dusting and big-bag packing systems are included in the accessories upon request range.Blade granulator model C-2545

Hopper

Front loading hopper completely soundproofed. No. 2 polyurethane flaps to reduce noise leakage and to avoid flyback of material from the cutting chamber. Servo-assisted manual tilting system, equipped with gas shock absorber.

Cutting chamber

Cutting chamber made entirely with parts fixed with bolts and pins, for a quick restoration of all construction components. Bearing support outside the cutting chamber to avoid any contamination from dust and liquids. Nr. 2 fixed reversible blades, mounted on two seats with wear compensation device. All the internal surfaces of the cutting chamber are carefully machined with a high degree of finish to facilitate cleaning operations. Frontal adjustment system of the fixed blades “EasyAccess Cumberland”.

Rotor

Self cooling open rotor with perfectly balanced central axis equipped with thick rotating blade supports. Double cutting angle system with “scissor effect” for greater efficiency, less noise and lower energy consumption. The rotor is mounted side-by-side with two rotating discs, to prevent filamentary materials from wrapping around the blade holder axis. This system, thanks to special internal fins, also provides cooling of the side walls and bearings.

Blade granulator model C-3045

Hopper

Hopper for frontal loading or with conveyor belt, completely soundproof. Nr. 3 polyurethane flaps to reduce noise leakage and to avoid the flyback of the material from the cutting chamber. Servo-assisted manual tilting system, equipped with gas shock absorber.

Cutting chamber

Cutting chamber made entirely with parts fixed with bolts and pins, for a quick restoration of all construction components. Bearing support outside the cutting chamber to avoid any contamination from dust and liquids. Two fixed reversible blades, mounted on two seats with wear compensation device. All the internal surfaces of the cutting chamber are carefully machined with a high degree of finish to facilitate cleaning operations. Frontal adjustment system of the fixed blades “EasyAccess Cumberland”.

Rotor

Self cooling open rotor with perfectly balanced central axis equipped with thick rotating blade supports. Double cutting angle system with “scissor effect” for greater efficiency, less noise and lower energy consumption. The shape of the cutting chamber and the rotor make it easier to grip bulky elements, minimizing the “bounce effect” on the rotating blades. The rotor is mounted side-by-side with two rotating discs to prevent filamentary materials from wrapping around the blade axis. This system, thanks to special internal fins, also provides cooling of the side walls and bearings.

Blade granulator model C-4070-3K

Hopper

Hopper for frontal loading or with conveyor belt, completely soundproof. Nr. 3 polyurethane flaps to reduce noise leakage and to avoid the flyback of the material from the cutting chamber. Servo-assisted manual tilting system for easy cleaning and maintenance.

Cutting chamber

Cutting chamber made entirely with parts fixed with bolts and pins, for a quick restoration of all construction components. Bearing support outside the cutting chamber to avoid any contamination from dust and liquids. Two fixed reversible blades, mounted on two seats with wear compensation device. All the internal surfaces of the cutting chamber are carefully machined with a high degree of finish to facilitate cleaning operations. Frontal adjustment system of the fixed blades “EasyAccess Cumberland”.

Rotor

Self cooling open rotor with perfectly balanced central axis equipped with thick rotating blade supports. Double cutting angle system with “scissor effect” for greater efficiency, less noise and lower energy consumption. The shape of the cutting chamber and the rotor make it easier to grip bulky elements, minimizing the “bounce effect” on the rotating blades. The rotor is mounted side-by-side with two rotating discs to prevent filamentary materials from wrapping around the blade axis. This system, thanks to special internal fins, also provides cooling of the side walls and bearings.

ISVE shredding systems

The shredders, grinders, granulators and the wide range of Isve accessories provide production lines specific to the recovery, reuse or disposal of production waste. As accomplishments stand the lines for shredding, separation, washing and drying of plastic materials from self-destruction, such as the recovery and separation line of car tyres` rubber. Production up to 1 t/h. ISVE is capable of combining all the various types of grinders and granulators to obtain complete systems equipped with conveyer belts, iron removal systems, pneumatic handling and big-bag packaging systems.Below are some proposals:

- Grinding, iron removal and wood refining systems;

- Plastic material granulating, iron removal and grinding systems;

- Systems for grinding and shredding papers up to the DIN 5 specification (max safety)

- Systems for removing moisture or dust from ready-packed products (food and bottling industry). We have a 200 m 2 show room equipped for tests and ready to host customers willing to perform any kind of shredding test using the ISVE range of products.

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.