- Spare Parts

- knives | blades

- crown cutters | concave cutters

- counter knives | scraper blades

- granulator rotor knives | fly knives

- granulator static knives | bed knives

- rotor shear spare parts

- baling press knives

- other blades | pelletizing knives

- bolt-on cutting edges

- knife holders | knife pads

- sealing rings | wear rings

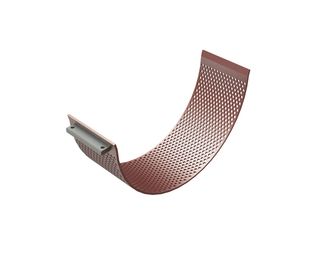

- screen baskets

- screen plates

- screen cassettes | screen holders

- screen accessories

- other spare parts | standard accessories

- electrics | hydraulics | pneumatics

- rotors

- transmission technology

- hardware | fastening material

- Manufacturers

- Vecoplan LLC (Retech)

- Lindner Recyclingtech America

- Eldan Recycling

- Andritz Mewa

- Able

- Alpine Hosokawa

- Amni Maschinenbau

- ARP

- Artech

- Austro

- Bano Recycling

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt spare parts

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Görgens Mahltechnik

- Gross

- Guidetti

- Haas

- Hammel Recyclingtechnik

- Herbold Meckesheim USA

- HSM

- ISVE

- Jenz

- Kueny

- MACPRESSE

- Molinari Recycling

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero | Sorema

- Rapid

- Reto Redoma

- Rudnick & Enners

- STF

- THM Recycling

- Tria

- Untha America

- Vogelsang

- Wagner Shredder

- Wanner

- Weima America

- Wipa

- Zeno

- Zato

- Zerma America

BHS

Spare parts from CUTMETALL

For your BHS Sonthofen plant you will find a comprehensive range of suitable CUTMETALL spare parts and wear parts such as counter knives, screen baskets, knife holders and other spare parts suitable for the following model series of BHS Sonthofen, among others:

-

BHS Universal-Shredder (NGU)

-

BHS Rotorschere (VR)

-

BHS Rotorshredder (RS)

-

BHS Rotor-Granulator (NGV)

» Further information about the manufacturer BHS Sonthofen you will find in the following.

Who is BHS-Sonthofen GmbH

The origins of BHS-Sonthofen go back to the year 1607. What began as a diocesan iron-smelting works evolved into an internationally leading technology company.Whether mixing, crushing, recycling, filtering, drying or reacting: BHS-Sonthofen uses its process engineering expertise to modify source materials in such a way that new values are created for customers. The international customers come from a wide range of industrial sectors, from the chemical and pharmaceutical industry, through the building materials industry to the recycling and environmental sector.

THE BUSINESS UNIT RECYCLING & ENVIRONMENT

BHS-Sonthofen is the technology leader in the processing of metal-containing composites and a specialist for hazardous and organic waste. The company covers complete recycling processes with know-how and innovative processes and plants.The right recycling solution for every need

The Recycling & Environment Division of BHS-Sonthofen offers a comprehensive range of machines, processes and full-scale plants for the recycling industry, waste disposal and environmental technology. A comprehensive portfolio of recycling machines is available for the effective processing as well as pre- and post-shredding of a wide range of recyclable and waste materials. Depending on requirements, this includes machines implementing crushing, cutting or tearing technology. Customers benefit from obtaining solutions from a single vendor: BHS-Sonthofen accompany the entire process from consulting, process development and profitability analysis through to the planning and commissioning of turnkey recycling plants.

THE SOLUTIONS IN THE BUSINESS AREA RECYCLING AND ENVIRONMENT

Metalliferous compositesBatteries

Incinerator bottom ash

Metallurgical and ironworks slags

Residual materials from shredders

Light metal scrap

Hazardous waste

Shredding mixing pumping

Waste stabilization

Industrial sludge

Mercurial waste

Harbor dredging

Household & industrial waste

Refuse-derived fuels

Drywall

Tyre

Biomass

Substrate processing

MACHINES FROM BHS-SONTHOFEN FOR RECYCLING AND ENVIRONMENT

Rotorshredder (RS)

Impact crusher (PB) & Impact mill (PM)

Rotor centrifugal crusher (RSMX)

Rotor impact mill (RPMV & RPMX)

Cutting & tearing shredding

Rotary shear (VR)

Universal Shredder (NGU)

Biomass crushers

Biogrinder (RBG)

FURTHER BUSINESS UNITS

FILTRATION

BHS-Sonthofen is the expert for cake forming filtration - with comprehensive know-how the company finds the optimal separation solution for its customers.

MIXING & CRUSHING

For more than a century BHS-Sonthofen has been a pioneer in mixing and size reduction technology. The processes set industry standards.

DRY & REACT

The core competence of the subsidiary AVA are individually tailored solutions in the areas of drying, mixing, reacting, evaporating, sterilising and granulating.

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.