- Spare Parts

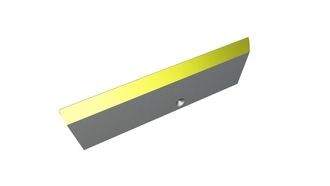

- knives | blades

- crown cutters | concave cutters

- counter knives | scraper blades

- granulator rotor knives | fly knives

- granulator static knives | bed knives

- rotor shear spare parts

- baling press knives

- other blades | pelletizing knives

- bolt-on cutting edges

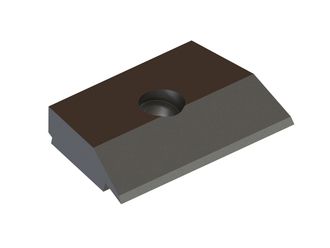

- knife holders | knife pads

- sealing rings | wear rings

- screen baskets

- screen plates

- screen cassettes | screen holders

- screen accessories

- other spare parts | standard accessories

- electrics | hydraulics | pneumatics

- rotors

- transmission technology

- hardware | fastening material

- Manufacturers

- Vecoplan LLC (Retech)

- Lindner Recyclingtech America

- Eldan Recycling

- Andritz Mewa

- Able

- Alpine Hosokawa

- Amni Maschinenbau

- ARP

- Artech

- Austro

- Bano Recycling

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt spare parts

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Görgens Mahltechnik

- Gross

- Guidetti

- Haas

- Hammel Recyclingtechnik

- Herbold Meckesheim USA

- HSM

- ISVE

- Jenz

- Kueny

- MACPRESSE

- Molinari Recycling

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero | Sorema

- Rapid

- Reto Redoma

- Rudnick & Enners

- STF

- THM Recycling

- Tria

- Untha America

- Vogelsang

- Wagner Shredder

- Wanner

- Weima America

- Wipa

- Zeno

- Zato

- Zerma America

Erema

Spare parts from CUTMETALL

In this section we present our extruder knives, scrapers, knife holders, rotor knives as well as other spare parts and wear parts suitable for the following Erema model series:

-

Erema INTAREMA® TVEplus®

-

Erema TVE

Who is Erema

EREMA Engineering Recycling Maschinen und Anlagen Ges.m.b.H., based in Ansfelden, Austria, is one of the world's leading developers and manufacturers of plastics recycling machines and system components. In 1983 Georg Wendelin, Helmut Bacher and Helmuth Schulz founded the company, of which more than 6,500 systems are now in operation around the globe. Highly valued for their degree of innovation, robustness and operational reliability. In total, they produce more than 14.5 million tonnes of plastic pellets of the highest quality each year, adapted to the respective requirements.

Highly qualified specialists continuously research the development of new recycling systems and perfect existing machines. 115 patent families with more than 1,000 patents prove the innovative strength of the company.

EREMA is part of the EREMA Group, to which PURE LOOP, 3S and UMAC also belong. Including the subsidiaries in the USA, China and Russia, the group is represented by more than 50 national agencies on five continents. Regardless of which aspect of plastics recycling is required: Customers always benefit from the know-how and tailor-made solutions offered by all the companies in the group.

EREMA offers individual recycling systems for:

- all thermoplastics such as PE, PP, PET, PS, ABS, PA, PC, biopolymers or compounds

- in various forms such as films, regrind, hollow bodies, foam, fibres, ribbons, etc.

- in the fields of in-house and industrial recycling, post consumer recycling, bottle recycling and special materials

The areas of application are:

Inhouse- | Industrial Recycling Post Consumer Recycling Bottle Recycling Special MaterialsInhouse- und Industrial Recycling

EREMA's in-house recycling systems turn alleged production waste into new raw material on the spot. With recycling rates of up to 100 percent. Technological ingenuity, seamless integration into existing processes and the easiest possible operation speak for themselves. All in-house recycling systems are equipped with EREMA's Counter Current technology. This ensures maximum throughput and greater flexibility with regard to materials. And thanks to ecoSAVE® and a range of other eco measures, the machines are also real energy-saving champions that set the standard for energy efficiency.

Typical in-house materials and suitable EREMA machines:

- Non-printed films and blown films: INTAREMA® T

- Non-printed edge trim: INTAREMA® K live, INTAREMA® T live and INTAREMA® TE live

- Edge trim: INTAREMA® K

- Lightly printed films: INTAREMA® TE

- Heavily printed / metallized films: INTAREMA® TVEplus

- BOPP films: INTAREMA® T

- BOPET films: INTAREMA® T-DD

- Multiple-layer films such as PET/PE: COREMA

- Sacking fabric/Raffia: INTAREMA® T, INTAREMA® TE

- PP non-woven: INTAREMA® T, INTAREMA® TE

- PP filaments: INTAREMA® T, INTAREMA® TE

- PP fibres: INTAREMA® T, INTAREMA® TE

Post Consumer Recycling

In times of dwindling and expensive primary raw materials, post consumer waste is becoming increasingly valuable in the case of plastics. High quality reprocessing makes it a profitable, almost inexhaustible resource. This promotes the company's own business and helps to avoid environmentally harmful landfills. Heavy contamination and mixing are just two of the many complex challenges facing post consumer plastics.

EREMA also offers powerful, environmentally friendly technologies in this special field. Best possible quality, highest performance, maximum output are the strengths of the recycling plants.

Typical post consumer recycling materials and suitable EREMA machines:

- PW washed shreds: INTAREMA® TVEplus®

- Washed shreds/ agricultural sheeting: INTAREMA® TVEplus®

- PE films with paper labels: INTAREMA® TVEplus®

- PE film / non woven fleece with solid content: INTAREMA® TVEplus®

- Regrind material, thick: INTAREMA® RegrindPro®

- Regrind material, thin: INTAREMA® RegrindPro®

- HDPE regrind material: INTAREMA® RegrindPro®

Bottle Recycling

Uncompromising food suitability, IV stability, safety and best energy efficiency. EREMA knows what is important in bottle-to-bottle recycling and rPET inline applications. The company successfully demonstrates this with its leading VACUREMA® and VACUNITE® systems, which process more than 1.2 million tonnes of PET into rPET every year worldwide.

EREMA technology ensures that the quality of the end product is not only high but also remains consistently high. Even if the properties of your input material change permanently - for example in terms of moisture and bulk density or IV values.

Typical bottle recycling materials and suitable EREMA machines:

- PET bottle flakes: VACUNITE®

- HDPE bottle flakes: VACUREMA®

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.