screen plates

by CUTMETALL your sparepart specialist

At CUTMETALL you can find suitable screen plates for many models by renowned shredding machine manufacturers, such as Hosokawa Alpine, Bano, Dreher, Eldan, Weima, and Lindner Recyclingtech to list a few.

You have got enough on your plate... To make finding the screen plate right for your machine as easy as possible we have added filters to narrow down your search.

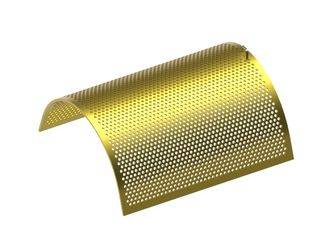

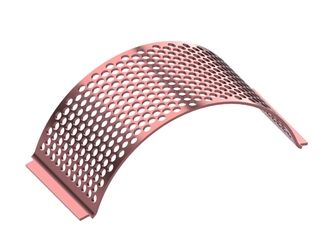

Screen plates

Screen plates play a vital role in granulators used in the recycling industry. They break down the material into smaller sizes and shapes, making it easier to handle and transport.

A screen plate is a perforated plate that fits into the granulator's cutting chamber, and it comes in different shapes, sizes, and hole patterns. The size of the holes determines the size of the particles that pass through it. The screen plates' holes come in different sizes, depending on the desired particle size and application.

During the shredding process, material enters the granulator through a hopper and contacts the rotor and fly knives. The rotating rotor forces the material through the holes in the screen plate. The smaller particles that pass through the holes go into a collection bin, while larger particles go back to the cutting chamber for further shredding.

Screen plates are made from various materials, including hardened tool steel and stainless steel, to withstand the wear and tear of the shredding process. They can also be customized to fit specific granulator models and applications.

To keep the screen plates functioning properly and prevent clogging, it's necessary to regularly inspect and replace worn or damaged ones. Clogging can reduce the shredding process's efficiency and damage the granulator. Proper cleaning and maintenance can help prevent clogging and ensure consistent performance.

In conclusion, screen plates are essential to the shredding and recycling process, breaking down the material into smaller particles for easier handling and transport. With proper maintenance and replacement, screen plates can provide efficient and reliable operation in the recycling industry.

Need more information on our screen plates?

Our extensive screen plate product range includes numerous variants.

Not sure which screen plate is right for you? We are here to assist you in finding the replacement screen plate best suited to your specific task.

Want to know whether and how the service life and durability of your machines can be extended? Reach out to our Sales team. We would like to show you how CUTMETALL products optimize your break down processes!

Your CUTMETALL team!

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.