screen baskets

by CUTMETALL your sparepart specialist

CUTMETALL supplies suitable screen components for various models and product lines by a number of renowned manufacturers, including Lindner Recyclingtech, Vecoplan, Weima, Gross, Eldan, Untha, Zeno, Neue Herbold and many more.

Try the filter options to simplify your search for the screen basket right for your shredder.

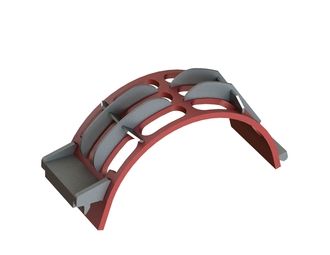

Screen baskets

Screen baskets are an important part of granulators used in recycling. They divide the ground material into various sizes and shapes, making it easier to handle and transport.

The screen basket is a cylindrical container that fits over the granulator rotor. It's made up of plates with different sized holes that determine the size of the particles that pass through it. The screen basket can be changed easily, allowing operators to adjust the hole size to fit different needs.

During the shredding process, material is fed into the granulator through a hopper and contacts the rotor and fly knives. The rotating rotor forces material through the holes in the screen basket. Smaller particles pass through the holes and go into a bin, while larger particles go back to the cutting chamber for further shredding.

Screen baskets can be made from various materials, including stainless steel and hardened tool steel, to withstand wear and tear. They can also be customized to fit specific granulator models and applications.

To keep the screen basket functioning properly and prevent clogging, regular maintenance and cleaning are essential. Clogging can reduce the shredding process efficiency and damage the granulator. It's necessary to inspect and replace worn or damaged screen baskets to ensure consistent performance and prevent downtime.

In conclusion, screen baskets are critical to the shredding and recycling process by separating ground material into different sizes and shapes. With proper maintenance and replacement, screen baskets can provide efficient and reliable operation in the recycling industry.

Need more information on our screen baskets?

At CUTMETALL you will find lots of screen baskets for all kinds of shredders and break-down applications.

Should a suitable screen basket appear to not be listed, please contact us. We'll help you find the optimal screen basket for your machine and application.

We gladly also answer any questions you may have on whether and how to extend the service life and durability of your machines. Happy to advise you!

Your CUTMETALL team!

How you benefit from Spare parts by CUTMETALL

CUTMETALL products: More than a spare part! Tuning for your machine!

Our spare parts and wear parts are not original equipment manufacturer items (original parts of the machine manufacturers) but rather process-optimized CUTMETALL own brands: A perfect fit. Durable. Economical.