Refuse-derived

fuels (SRF | RDF)

Sustainable energy from waste

Household, commercial and industrial waste can be processed into high-quality solid recovered fuels and refuse-derived fuels (SDF | RDF). These fuels play a crucial role in energy production and contribute to reducing landfill waste.

CUTMETALL products support waste-to-energy manufacturers because we offer spare and wear parts that are specially optimized for waste fuel production.

View our products

CUTMETALL products support waste-to-energy manufacturers because we offer spare and wear parts that are specially optimized for waste fuel production.

View our products

+ 6.5M ↓

Over 6.5 million tons of household, commercial, and industrial waste are processed into high-quality substitute fuels (SRF | RDF) in Germany every year.

52% ↓

52% of the thermal energy requirements of the European cement industry alone are covered by SRF | RDF.

100% ↓

It's 100% sure: Alternative fuels play a decisive role in energy production and the reduction of landfill waste.

Efficient SRF Preparation with CUTMETALL

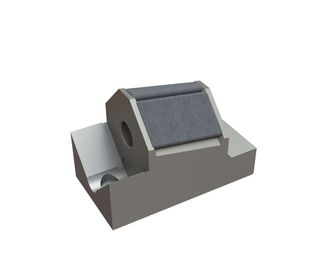

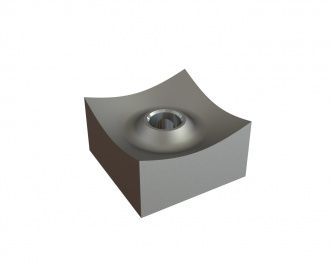

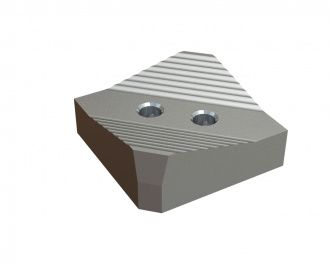

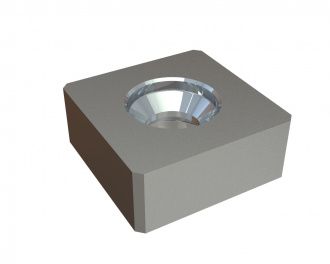

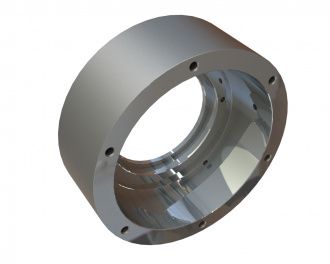

CUTMETALL supplies premium knives, knife holders, and screens for the production of solid recovered fuel (SRF). Our specially developed wear parts ensure machines operate at peak performance, helping clients produce high-quality fuel efficiently.

Our services for SRF processing:

- Tailored solutions: Customised cutting tools, such as our exclusive concave blade.

- Process analysis & consulting: We examine production workflows and advise on the best-fit components.

- Reduced downtime: Wear parts precisely matched to both machine and material.

- Quick availability: Many spare parts are visible and orderable directly in our online shop.

Register in the shop

An insight into substitute fuel production

Ready to take the next step? Let’s get going!

Interested in how refuse-derived fuel (RDF) is produced? Continue reading to explore the full process and key advantages. Scroll down

But what exactly are Solid Recovered Fuels (SRF)?

Solid Recovered Fuels (SRF) are produced by converting selected waste streams into energy-rich materials. These can replace fossil fuels in industrial applications such as cement works or power stations. The benefits include:

- Substitution of fossil fuels such as coal, oil, and gas

- Recovery of waste that cannot be materially recycled

- Protection of natural resources

- Lower CO₂ emissions

- Reduced waste volume

- Secure, long-term disposal options for waste generators

- Stable fuel supply for SRF end-users

Challenges in SRF Preparation

Producing SRF is not without its challenges. The input material — that is, the waste used to create the fuel — can vary significantly in composition. Whether it involves sorting residues, household waste or manufacturing by-products, each material behaves differently and requires machinery to be specifically adapted. Such flexibility is essential to generate fuels with the desired properties.

Wear parts are a particular focus here. The machine blades and screens responsible for shredding and sorting the waste must be replaced on a regular basis. Why? Because the hardness and characteristics of the input material differ, causing rapid wear. To ensure the consistent quality of the final output, these components must always be in top condition. Routine maintenance and equipment adjustments are therefore essential to meet the demands of cement plants and power stations.

Wear parts are a particular focus here. The machine blades and screens responsible for shredding and sorting the waste must be replaced on a regular basis. Why? Because the hardness and characteristics of the input material differ, causing rapid wear. To ensure the consistent quality of the final output, these components must always be in top condition. Routine maintenance and equipment adjustments are therefore essential to meet the demands of cement plants and power stations.

The sophisticated production process is broken down into defined stages.

How Are Solid Recovered Fuels Prepared?

Which Types of Waste Are Suitable for SRF Preparation?

A variety of waste types are suitable for producing SRF (Solid Recovered Fuel), particularly those with a high calorific value:

- Commercial and industrial waste

- Production waste

- Packaging waste

- Household waste (especially high-energy content fractions)

- Bulky waste

- Sewage sludge

- Timber waste

- Plastics

- Textiles

What Is the Impact of Solid Recovered Fuels on Waste Management and Resource Cycles?

Effects on Waste ManagementThe use of SRF brings several advantages for waste management. On the one hand, it reduces the volume of waste ending up in landfills. On the other, converting non-recyclable waste into energy helps decrease industrial reliance on fossil fuels. Nonetheless, challenges exist: the availability of SRF might discourage investment in recycling technologies. There is also a risk that materials suitable for recycling could end up being incinerated.

Impact on Resource Cycles

The cement industry, in particular, shows how SRF can positively affect raw material cycles. In Austria, for instance, 1.4 million tonnes of hard coal are replaced annually with SRF. Thanks to co-processing, the demand for virgin materials is reduced, with up to 17% of SRF contributing to material substitution.

Long-Term Considerations

The long-term effects of SRF use on recyclable material availability remain insufficiently studied. It is therefore important to find a balanced approach between energy recovery and material recycling. Top priority should be given to reuse and recycling, with SRF only being used when no material recovery is possible. At the same time, sorting and recycling technologies must evolve to maximise resource efficiency.

SRF can be a valuable element of waste management, as long as it is limited to non-recyclable waste. Striking the right balance between thermal and material recovery, while continuously improving recycling systems, is key to realising the benefits of SRF and safeguarding the circular use of raw materials.

Is the Use of Solid Recovered Fuels More Environmentally Friendly Than Burning Fossil Fuels Such as Coal or Gas?

The use of Solid Recovered Fuels (SRF) brings several clear environmental benefits compared to the combustion of fossil fuels such as coal or gas.

In conclusion, SRF can be a sustainable and environmentally sound alternative to fossil fuels—provided that it is handled correctly and quality standards are maintained. It reduces CO₂ emissions, conserves essential resources, and offers a long-term solution for non-recyclable waste management.

- Lowering CO₂ Emissions

SRF contributes significantly to the reduction of CO₂ emissions by substituting fossil fuels. As SRF releases less fossil-based carbon when burned, it helps lower the carbon footprint of industries like cement production. Overall, energy recovery from waste results in a marked decrease in CO₂ emissions compared to conventional fossil fuels. - Preserving Resources

Another advantage of SRF lies in conserving natural resources. These fuels are produced from waste that would otherwise be difficult to utilise. By using SRF, the consumption of finite and costly fossil resources is reduced—an increasingly important factor in light of global resource scarcity. - Efficient Waste Utilisation

SRF provides an effective approach to handling waste that cannot be recycled. This includes municipal, industrial, and commercial waste. Using SRF reduces the amount of material going to landfill, helping to save space and lower greenhouse gas emissions. - Challenges

Naturally, there are challenges involved in using SRF. The fuel must consistently meet stringent quality requirements to suit the operational demands of industrial facilities, such as cement works. This calls for precise processing and close monitoring to ensure that no harmful emissions are released.

In conclusion, SRF can be a sustainable and environmentally sound alternative to fossil fuels—provided that it is handled correctly and quality standards are maintained. It reduces CO₂ emissions, conserves essential resources, and offers a long-term solution for non-recyclable waste management.

What Are the Political and Regulatory Frameworks for SRF?

Political Incentives

Although there are no direct subsidies for the use of SRF, various environmental and climate policy measures provide indirect incentives. For instance, carbon pricing makes fossil fuels more expensive, thereby increasing the appeal of SRF. Waste policy objectives promoting landfill diversion also highlight the importance of alternative recovery routes such as SRF. Moreover, the EU Waste Hierarchy, which ranks energy recovery above landfilling, supports the deployment of SRF.

Market-Based Considerations

From a business standpoint, using SRF presents several advantages. Companies can reduce fuel costs by substituting fossil fuels with SRF. In addition, new markets and value chains are emerging within the waste management industry. Another positive aspect: plants running on SRF can achieve energy efficiencies up to 30% higher than conventional waste incineration. Nevertheless, economic viability strongly depends on prevailing conditions. Fluctuating fossil fuel prices can affect SRF’s competitiveness, and strict regulatory requirements regarding emissions and fuel quality may increase operational costs.

Hidden Costs and Risks

There are also long-term risks that should not be overlooked. Poor-quality SRF may release harmful emissions, posing risks to human health and the environment. Moreover, if recyclable materials are burned instead of being recovered, recycling potential is lost. This undermines the circular economy and may lead to increased environmental impact.

The use of SRF reflects a balance of market dynamics and political governance. While it delivers economic benefits, it requires robust regulation and consistent quality control. In the long term, the societal cost will depend on how well SRF deployment is managed and monitored.

Although there are no direct subsidies for the use of SRF, various environmental and climate policy measures provide indirect incentives. For instance, carbon pricing makes fossil fuels more expensive, thereby increasing the appeal of SRF. Waste policy objectives promoting landfill diversion also highlight the importance of alternative recovery routes such as SRF. Moreover, the EU Waste Hierarchy, which ranks energy recovery above landfilling, supports the deployment of SRF.

Market-Based Considerations

From a business standpoint, using SRF presents several advantages. Companies can reduce fuel costs by substituting fossil fuels with SRF. In addition, new markets and value chains are emerging within the waste management industry. Another positive aspect: plants running on SRF can achieve energy efficiencies up to 30% higher than conventional waste incineration. Nevertheless, economic viability strongly depends on prevailing conditions. Fluctuating fossil fuel prices can affect SRF’s competitiveness, and strict regulatory requirements regarding emissions and fuel quality may increase operational costs.

Hidden Costs and Risks

There are also long-term risks that should not be overlooked. Poor-quality SRF may release harmful emissions, posing risks to human health and the environment. Moreover, if recyclable materials are burned instead of being recovered, recycling potential is lost. This undermines the circular economy and may lead to increased environmental impact.

The use of SRF reflects a balance of market dynamics and political governance. While it delivers economic benefits, it requires robust regulation and consistent quality control. In the long term, the societal cost will depend on how well SRF deployment is managed and monitored.