Detailed description

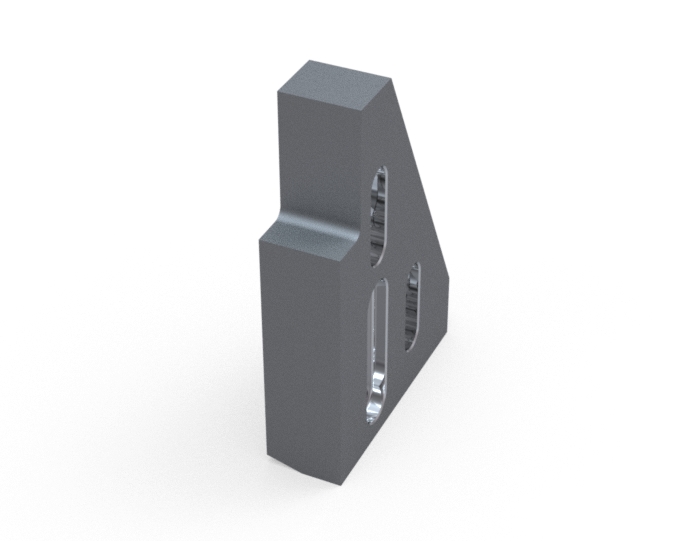

Counter knife GMED0245-99R-E by CUTMETALL for shredding machines by Eldan Recycling.

Compatibility with machines:

- Eldan SC 1412

- Eldan SC 2118

- Eldan SC

- Super Chopper

Cutting performance and durability:

Through the use of different materials and the variance in the cutting geometry, the spare part can be customised to the application area in terms of throughput and durability.

The W9-option wears more rapidly than the X-variant, but also has increased toughness and is insensitive to impurities. However, the hardness of the W9-version is lower than that of the X-variation.

Due to the through-hardening process, there is a uniform hardness from the edge layer to the core. This ensures consistent wear over the service life of the counter knife.

It is imperative to avoid the welding on or hardfacing of products of this variant, as the structure will otherwise be severely weakened. Consequently, breakage and machine damage may occur.

Fastening in the machine:

The counter knife is mounted right on the cutting device. The other parts of this set can be found under the accessories.

When attaching, please also ensure that the support of the knives is in a flat condition, as otherwise breakage may occur.

General characteristics:

The dimensions of the counter knife are 245.3mm long, 168.4mm wide and 50mm high.

The particular feature of our Eco Line, to which this counter knife belongs, is the lower price range compared to the Premium Line.

CUTMETALL Quality Replacement and Wear Parts — manufactured to fit Eldan Recycling Machines

At CUTMETALL, your specialist for replacement and wear parts, you will find a wide selection of components compatible with shredders, granulators, and raspers from Eldan Recycling. Our range includes knives, counter knives, screens, and many other components manufactured to fit various Eldan Recycling machine models.

With our CUTMETALL spares and wear parts we support operators of the following Eldan Recycling machine series, among others:

- Eldan Super Chopper (SC)

- Eldan Multi Purpose Rasper (MPR)

- Eldan Heavy Granulator (HG)

- Eldan Heavy Rasper (HR)

- Eldan Fine Granulator (FG)

- Eldan Heavy Pre Granulator (HPG)

If you don’t see your specific model or part listed, simply get in touch – our experienced team will be happy to help you find the right parts to support reliable operation in demanding recycling environments.

Benefits with CUTMETALL

CUTMETALL Products – Precision-fit. Durable. Efficient.

At CUTMETALL we draw on decades of experience in the recycling industry to provide a dependable combination of quality, fit and service.

Our specialists support you in selecting suitable parts for your shredding or size-reduction tasks and offer practical application advice tailored to your setup and material stream.

Discover our full range of parts compatible with Eldan machines here.

CUTMETALL is not affiliated with Eldan Recycling A/S. All brand names are used for identification and reference purposes only. Our spare and wear parts are not original parts of the machine manufacturers, but our CUTMETALL products - engineered for compatibility.