Tire Recycling

Each year, approximately 3.4 million tons of scrap tires are produced in Europe. Because they don’t break down naturally, worn-out tires require professional disposal. CUTMETALL products enable tire recyclers to optimise their equipment and generate premium rubber granulate and powder.

View our products

View our products

3.4M ↓

Every year, approximately 3.4 million tons of scrap tires are produced in Europe alone

20% ↓

In Germany, 20% of scrap tires are reused as used tires or casings.

+40% ↓

Over 40% are processed into granules and rubber powder in Germany. These materials are used in construction and noise reduction products, cargo securing systems, railroad track installations, and the cement industry.

Efficient Solutions for Tire Recycling with CUTMETALL

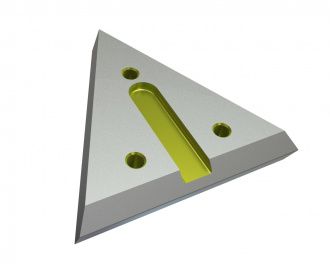

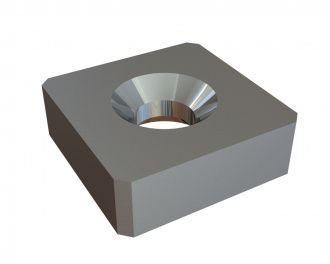

Tire recycling places heavy demands on machinery and wear parts. At CUTMETALL, we offer rugged, long-lasting components specifically built for these demanding applications.

Our advanced wear parts for recycling equipment are built for high durability. Here’s what that means for you:

- Extended service life of machine components

- Increased throughput and optimised equipment performance

- Uniform output material thanks to precision screens and perforations

- Reduced downtime due to high inventory availability

We offer replacement and wear parts for a wide range of trusted tire shredder brands such as MeWA Recycling, Eldan Recycling, Artech, Adelmann, BHS, THM Recycling and Herbold.

Sign up for the online shop

An overview of scrap tire recycling

.png)

.png)

Ready to take the next step? Start now!

Want to learn more about scrap tire recycling? Dive into the process and discover the benefits.

Read more

Read more

What Impact Does Tire Recycling Have?

Scrap tire recycling is an important step toward protecting the environment and conserving critical resources. In Germany, the Circular Economy Act ensures that old and worn-out car tires are not just thrown in the trash but are properly collected and recycled.There are several ways tires can be reused: They may be retreaded by adding a new rubber layer to the existing casing, broken down into their raw components for reuse, or subjected to thermal processing for energy recovery.

What are the challenges in tire recycling?

The main challenges in tire recycling stem from the complex composition of the tire:

Only with regular wear part replacement can recycling systems maintain peak performance. This ensures a high-quality rubber end product — helping recyclers stand out as dependable suppliers.

- Toxic ingredients: Modern tires contain carbon black that includes hazardous polycyclic aromatic hydrocarbons (PAHs), making recycling difficult and harmful to the environment.

- High steel content: About 18% of a tire is steel, especially in the bead wires. This steel needs to be separated before the tires can be shredded.

- Heavy wear and tear: The hard steel causes major damage to recycling machinery. The equipment operates under constant stress and must frequently have its wear parts replaced.

Only with regular wear part replacement can recycling systems maintain peak performance. This ensures a high-quality rubber end product — helping recyclers stand out as dependable suppliers.

How does making tires from recycled materials affect the environment compared to producing brand-new tires?

Producing tires with recycled materials delivers major environmental advantages over using new primary resources:

Lower Fossil Resource Consumption:

Incorporating recycled materials like PET bottles or scrap tires helps reduce the reliance on fossil-based inputs. Companies like Continental already use up to 28% sustainable raw materials from bio-based or circular sources.Lower Energy Use:

Making polyester yarn from recycled PET requires far less energy than using new raw materials — saving resources and shrinking the environmental footprint.Reduced Waste:

By repurposing PET bottles — about 9 to 15 per tire — and other materials, we prevent waste from being sent to landfills or incinerators.Reducing CO₂ Emissions:

The use of recycled materials significantly decreases CO₂ emissions in tire production, helping minimise the ecological footprint.Preserving Natural Resources:

Alongside recycled plastics, by-products from the paper and wood industries and rice husks are also utilised, contributing to the conservation of valuable natural resources.Supporting the Circular Economy:

Incorporating recycled materials into production helps build an effective circular economy, where raw materials stay in circulation for as long as possible.

Despite these benefits, it’s important to recognize that environmental performance can differ based on the recycling process and materials involved.

Additionally, tire quality must be sufficient to ensure longevity and maximise environmental gains.

Regulatory Framework for Tire Recycling – Germany as an Example

Tire recycling in Germany follows strict legal guidelines set out by the Circular Economy Act and waste tire regulations. A central component is the landfill ban, which encourages sustainable recovery paths and improves recycling rates.Manufacturers and importers are required to collect and properly recycle used tires, helping stabilize the market. Government funding programs also support the development of innovative recycling technologies.

Legally defined quality standards help drive demand for high-quality recycled products and promote their use across industries — supporting a truly circular economy.

Differences in Tire Recycling between Germany and the U.S.

How does the regulatory framework differ?

In Germany, tire recycling is tightly governed by the Circular Economy Act and the Waste Tire Ordinance. A landfill ban ensures that scrap tires do not end up in landfills. In the U.S., regulations vary by state since there is no federal landfill ban.

Who is responsible for tire recycling?

In Germany, manufacturers and importers are legally required to organize the collection and recycling of end-of-life tires. In the U.S., responsibility often falls to state or local governments, resulting in a patchwork of regulations.

What are the recycling rates?

Germany achieves a recovery rate of about 90%, supported by strict laws and well-established systems. In the U.S., recycling rates vary significantly from state to state.

What recycling methods are used?

Germany relies on material recovery and energy recovery — for example, in cement kilns. In the U.S., more tires are still landfilled, but innovative uses like asphalt mixing are emerging.

How is the tire recycling market structured?

The German market is centralised, dominated by a few large players. In contrast, the U.S. market is more fragmented, with many regional recyclers.

How about research and development?

Germany invests heavily in advanced recycling technologies and innovative applications, backed by government funding. The U.S. also conducts R&D, but with less coordination at the national level.

What is public awareness like?

Germany has a strong environmental culture, and recycling is widely accepted. In the U.S., public awareness is growing, but still varies greatly across regions.

Conclusion: Germany has a unified and stringent system, whereas the U.S. presents opportunities for progress through national coordination and innovation in recycling.

In Germany, tire recycling is tightly governed by the Circular Economy Act and the Waste Tire Ordinance. A landfill ban ensures that scrap tires do not end up in landfills. In the U.S., regulations vary by state since there is no federal landfill ban.

Who is responsible for tire recycling?

In Germany, manufacturers and importers are legally required to organize the collection and recycling of end-of-life tires. In the U.S., responsibility often falls to state or local governments, resulting in a patchwork of regulations.

What are the recycling rates?

Germany achieves a recovery rate of about 90%, supported by strict laws and well-established systems. In the U.S., recycling rates vary significantly from state to state.

What recycling methods are used?

Germany relies on material recovery and energy recovery — for example, in cement kilns. In the U.S., more tires are still landfilled, but innovative uses like asphalt mixing are emerging.

How is the tire recycling market structured?

The German market is centralised, dominated by a few large players. In contrast, the U.S. market is more fragmented, with many regional recyclers.

How about research and development?

Germany invests heavily in advanced recycling technologies and innovative applications, backed by government funding. The U.S. also conducts R&D, but with less coordination at the national level.

What is public awareness like?

Germany has a strong environmental culture, and recycling is widely accepted. In the U.S., public awareness is growing, but still varies greatly across regions.

Conclusion: Germany has a unified and stringent system, whereas the U.S. presents opportunities for progress through national coordination and innovation in recycling.

.png)