- Pièces de rechange

- Couteaux de recyclage

- Couronnes de coupe

- Contre couteaux

- Couteaux de rotor

- Couteaux de stator

- Lames de cisailles rotatives

- Couteaux de presse

- Lames de granulés

- Lames de godet

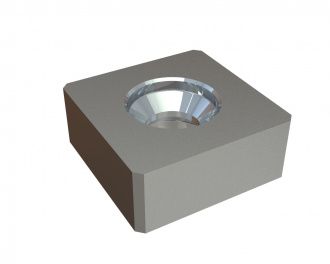

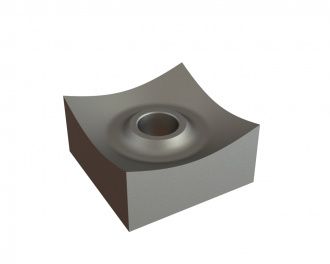

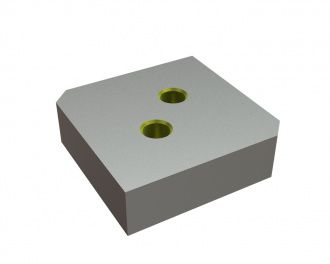

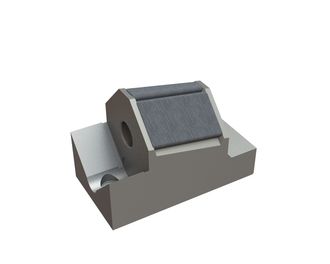

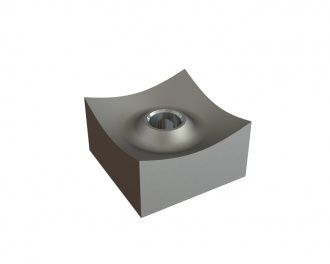

- Porte-couteaux de broyeur

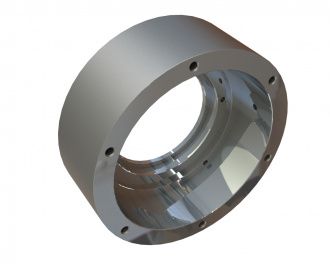

- Bagues d'étanchéité | Bagues d'usure

- Tamis | Paniers à tamis

- Tamis | Panneaux de tamisage

- Cassette-tamis | Supports de tamisage

- Accessoires de tamisage

- Autres accessoires

- électricité | hydraulique | pneumatique

- Rotors

- Technologie de transmission

- Pièces et fixations standard

- Fabricants

- Vecoplan

- Lindner Recyclingtech

- Eldan Recycling

- Able

- Alpine Hosokawa

- Amni

- ARP

- Artech

- Austro

- Bano

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Getecha

- Görgens

- Gross

- Guidetti

- Haas Recycling

- Hammel

- Herbold Meckesheim

- HSM

- ISVE

- Jenz

- Kueny

- MACPRESSE

- Molinari

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero

- Rapid Granulator

- Redoma & Reto Recycling

- Rudnick & Enners

- STF

- THM Recycling

- Tria

- Untha

- Vogelsang

- Wagner

- Wanner

- Weima Maschinenbau

- Wipa

- Zato

- Zeno

- Zerma

Applications

Nous vendons des solutions!

Nous fournissons à nos clients des solutions personnalisées pour leur domaine d'application, avec lesquelles vous pouvez optimiser l'ensemble de votre processus de recyclage et ainsi travailler de manière plus économique. Nous affirmons que nos clients bénéficient de durées de vie plus longues, de moins de temps d'arrêt et donc d'un gain de temps énorme grâce à la qualité CUTMETALLL fournie. Ce faisant, nous nous concentrons sur l'ensemble du processus de recyclage et nous essayons à tout moment, en collaboration avec nos clients, de répondre aux circonstances, aux exigences et aux besoins particuliers et de fournir des solutions et des concepts coordonnés.Nous nous appuyons sur notre expérience, notre expertise et notre savoir-faire, que nous pouvons offrir à nos clients directement et entièrement depuis notre entreprise. Du développement à la production de tous les composants, en passant par les tests et les contrôles, nous garantissons tout d'une seule source.

Challenges

In the recycling industry, the area of substitute fuels is unique, indeed. As different types of recyclable input come together, the machines have to be adapted and configured to a wide variety of conditions. The mixed material often causes high humidity in the machines, which in many cases can lead to corrosion of the components and thus reduce the throughput performance. Subsequently wear parts have to be changed frequently and the machine downtime is accordingly high.

Typical problems

Due to the inhomogeneous and mixed input made up of steel, household waste, commercial waste and manufacturing waste, the machines cannot be adapted to any specific input material. The different conditions of the materials must be taken into account at all times. Typical issues are, for example, the rusting of side walls due to the high humidity, or high downtime, due to the frequent need for replacement knives.

Advantages of CUTMETALL products

CUTMETALL designed hollow cove knives and knife holders specifically tailored to the area of making substitute fuels. These innovatove components make for a considerably higher throughput in the machines. The downtime can also be shortened considerably by a customized configuration and easier replacement of the wear parts. With its durable materials, individually adapted wear parts for the respective input and complete solutions for primary and secondary cutting, CUTMETALL guarantees a smooth process.

Industry information

The scarcity of fossil fuels worldwide and the increasing demand for energy demand new concepts that take care of energy generation for the future. With the production of substitute/alternative fuels, it has been possible to address the pproblem: the professional disposal of waste and recycling to substitute fuels is sensibly linked. The substitute/alternative fuels can adequately replace up to 100% of the primary substances, for example in the cement production: Here the ash of the substitute fuels can be reused in the cement.

The protection of natural resources and simultaneously environmentally friendly energy production are the direct advantages of the replacement fuel recycling.

The protection of natural resources and simultaneously environmentally friendly energy production are the direct advantages of the replacement fuel recycling.

Products used